carbon steel plate,steel coil,stainless steel plate,china export service provider.

carbon steel plate,steel coil,stainless steel plate,china export service provider.

304 304L 304H belongs to austenitic stainless steel, it is the most widely used in the 300 series materials. On the whole, the 304 304L 304H has very similar characteristics, the only difference lies in the level of carbon content, so there will be a little difference more or less in the application filed, but the overall application is the same.

304L has lower carbon content and better corrosion resistance. But 304 of the strength is higher than 304L, so 304 has a higher strength than 304L, and 304H has the best strength, because the carbon content is the highest among the three.

From the application: 304 can be widely used in various departments, various fields. 304L is mainly used in welding and other fields. 304H is mainly used in high temperature resistance, corrosion resistance and other fields, also used in fields such as welding, bending, and cold deformation ability is very good, has a very high stability and enduring strength, can work in the high temperature of 650 degrees Fahrenheit

Details for 304H material: 304H is a kind of stainless steel, with good bending, welding process performance, corrosion resistance, high durability and organizational stability, cold deformation ability is very good. The highest temperature can reach 650 DEG C, and the oxidation resistance is up to 850 DEG C

Surface treatment

|

Item |

Surface Finishing |

Surface finishing methods |

Main Applications |

|

NO.1 |

HR |

Heat treatment after hot rolling, pickling, or with treatment |

For without the purpose of the surface gloss |

|

NO.2D |

Without the SPM |

Method of heat treatment after cold rolling, pickling surface roller with wool or eventually a light rolling a matte surface processing |

General materials,building materials. |

|

BA |

Bright annealed |

Bright heat treatment after cold rolling , in order to be more shiny, cold light effect |

Automotive parts, home appliances, vehicles, medical equipment, food equipment |

|

NO.3 |

Shiny, coarse grain processing |

The NO.2D or NO.2B processing timber No. 100-120 polishing abrasive grinding belt |

Building materials, kitchen supplies |

|

NO.4 |

After CPL |

The NO.2D or NO.2B processing timber No. 150-180 polishing abrasive grinding belt |

Building materials, kitchen supplies, vehicles, medical and food equipment |

|

240# |

Grinding of fine lines |

The NO.2D or NO.2B processing timber 240 polishing abrasive grinding belt |

Kitchen appliances |

|

320# |

More than 240 lines of grinding |

The NO.2D or NO.2B processing timber 320 polishing abrasive grinding belt |

Kitchen appliances |

|

400# |

Close to BA luster |

The MO.2B timber 400 polishing wheel polishing method |

Building materials, kitchen utensils |

|

HL(hair lines) |

Polishing line having a long continuous processing |

In a suitable size ( usually mostly No. 150-240 grit ) abrasive tape for as long as the hair, having a continuous processing method of polishing line |

The most common building materials processing |

|

NO.6 |

NO.4 processing less than the reflection , the extinction |

NO.4 processing material used for polishing Tampico brushing |

Building materials, decorative |

|

NO.7 |

Highly accurate reflectance mirror processing |

No. 600 of the rotary buff with a polishing |

Building materials, decorative |

|

NO.8 |

Highest reflectivity mirror finish |

Fine particles of abrasive material in order polishing , mirror polishing with a polishing |

Building materials, decorative, mirrors |

|

Dimensions |

ASTM, ASME and API |

|

Standard |

ASTM A240 / ASME SA240 |

|

Width |

1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, |

|

Thickness |

4mm-100mm |

|

Length |

2000mm, 2440mm, 3000mm, 5800mm, 6000mm, |

|

Form |

Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

|

Surface Finish |

2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, chequered, embossed, hairline, sand blast, Brush, etching, Hot rolled plate (HR), Cold rolled sheet (CR), SATIN (Met with Plastic Coated) etc |

|

Hardness |

Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc |

Equivalent Grades of 304/304L/304H Stainless Steel Sheets

|

STANDARD |

WERKSTOFF NR. |

UNS |

JIS |

BS |

GOST |

AFNOR |

EN |

|

SS 304 |

1.4301 |

S30400 |

SUS 304 |

304S31 |

08Х18Н10 |

Z7CN18‐09 |

X5CrNi18-10 |

|

SS 304L |

1.4306 / 1.4307 |

S30403 |

SUS 304L |

3304S11 |

03Х18Н11 |

Z3CN18‐10 |

X2CrNi18-9 / X2CrNi19-11 |

|

SS 304H |

1.4301 |

S30409 |

– |

– |

– |

– |

– |

|

SS 304LN |

1.4311 |

S30409 |

– |

– |

– |

– |

– |

Chemical Composition

|

Grade |

C |

Mn |

Si |

P |

S |

Cr |

Mo |

Ni |

N |

|

SS 304 |

0.08 max |

2 max |

0.75 max |

0.045 max |

0.030 max |

18 – 20 |

– |

8 – 11 |

– |

|

SS 304L |

0.035 max |

2 max |

1.0 max |

0.045 max |

0.030 max |

18 – 20 |

– |

8 – 13 |

– |

|

SS 304H |

0.10 max |

2 max |

0.75 max |

0.045 max |

0.030 max |

18 – 20 |

– |

8 – 10.5 |

– |

Physical Properties

|

SS 304 |

||||||

|

Density |

Thermal Conductivity |

Electrical |

Modulus of |

Coefficient of |

Specific Heat |

Melting |

|

at 68°F: 0.285 |

9.4 at 212°F |

28.3 at 68°F |

28 |

9.4 at 32 – 212°F |

0.1200 at 68°F to 212°F |

2500 to 2590 |

|

|

12.4 at 932 °F |

39.4 at 752°F |

|

10.2 at 32 – 1000°F |

|

|

|

|

|

49.6 at 1652 °F |

|

10.4 at 32 – 1500°F |

|

|

|

SS 304H |

||||||

|

Denstiy |

Coefficient of |

Thermal Conductivity BTU/hr-ft-°F |

Specific Heat BTU/lbm -°F |

Modules of Elasticity (annealed)2-psi |

||

|

at 68 °F |

at 68 – 212°F |

at 68 – 1600°F |

at 212°F |

at 932°F |

at 32 – 212°F |

in tension (E) |

|

0.285 |

9.2 |

11.0 |

9.4 |

12.4 |

0.12 |

29 x 106 |

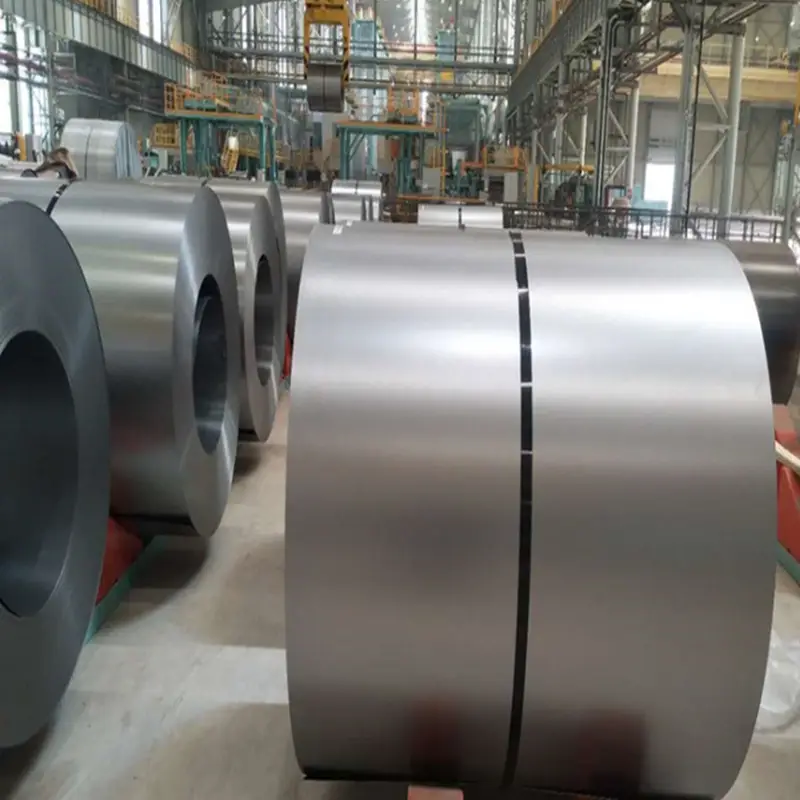

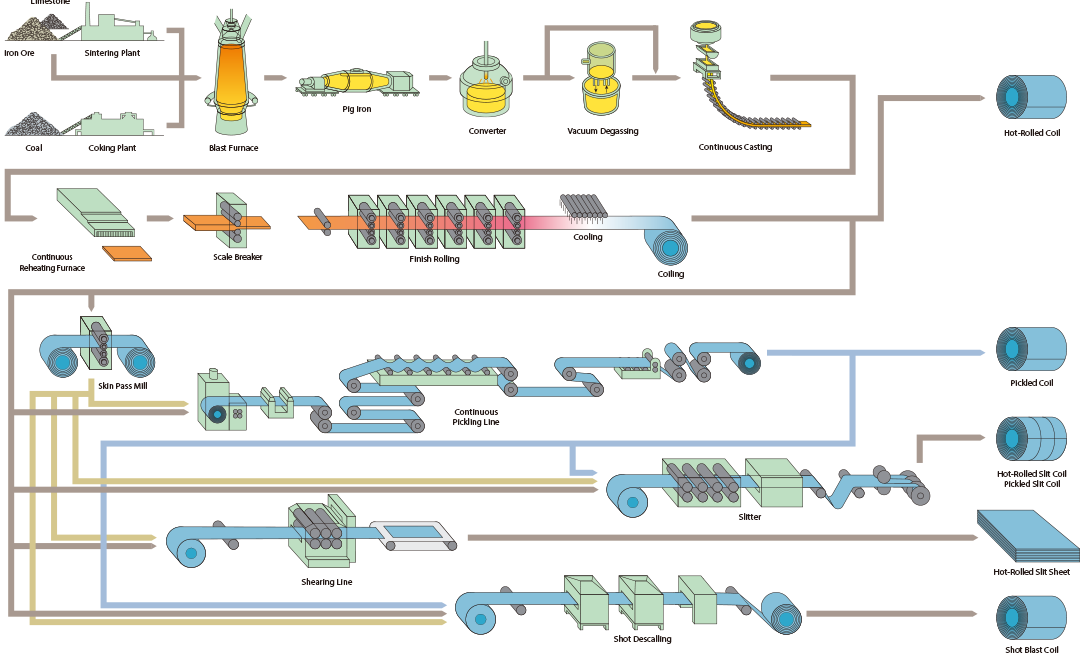

Hot-Rolled Steel Sheets and Coils

Cold-Rolled Steel Sheets and Coils