carbon steel plate,steel coil,stainless steel plate,china export service provider.

carbon steel plate,steel coil,stainless steel plate,china export service provider.

317/317L is a molybdenum-bearing austenitic stainless steel with greatly increased resistance to chemical attack as compared to the conventional chromium-nickel austenitic stainless steels such as Alloy 304. In addition, Alloy 317L offers higher creep, stress-to-rupture, and tensile strength at elevated temperatures than conventional stainless steels. It is a low carbon or "L" grade which provides resistance to sensitization during welding and other thermal processes.

Alloy 317L is a lowcarbon corrosion resistant austenitic chromium-nickel-molybdenum stainless steel. The high levels of these elements assure the alloy has superior chloride pitting and general corrosion resistance to the conventional 304/304L and 316/316L grades. The alloy provides improved resistance relative to 316L in strongly corrosive environments containing sulfurous media, chlorides, and other halides.

The low carbon content of Alloy 317L enables it to be welded without intergranular corrosion resulting from chromium carbide precipitation enabling it to be used in the as-welded condition. With the addition of nitrogen as a strengthening agent, the alloy can be dual certified as Alloy 317.

Alloy 317L is non-magnetic in the annealed condition. It cannot be hardened by heat treatment, however the material will harden due to cold working. Alloy 317L can be easily welded and processed by standard shop fabrication practices.

|

317 / 317L Sheets & Plates Specifications |

ASTM A240 / ASME SA240, BS EN 10088-2, en 10028-7, IS 6911 |

|

317 / 317L Sheets & Plates Dimension Standard |

MSRR, AMS, BS, JIS, AISI, ASTM, GB, DIN, EN, etc |

|

SS 317 / 317L Sheets & Plates Size Range |

Cold rolled ASME SA240 Grade 317 / 317L Stainless Steel Sheet 0.5-6.4 mm |

|

317 / 317L SS Sheets & Plates Width |

1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc |

|

SS 317 / 317L Sheets & Plates Length |

2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc |

|

SS 317 / 317L Sheets & Plates Thickness |

0.3 mm to 120 mm |

|

International Standard of Stainless Steel 317 / 317L Sheets & Plates |

ASTM A480 |

|

Tolerances (width / thickness) of Stainless Steel 317 / 317L Sheets & Plates |

EN 10258/ DIN 59381) |

|

Finish of SS 317 / 317L Sheets & Plates |

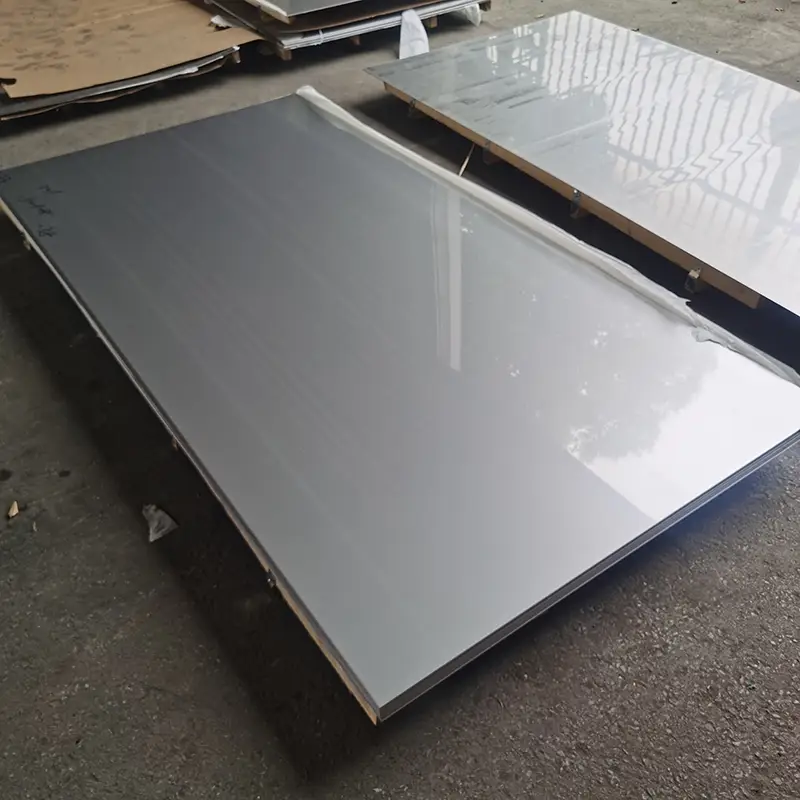

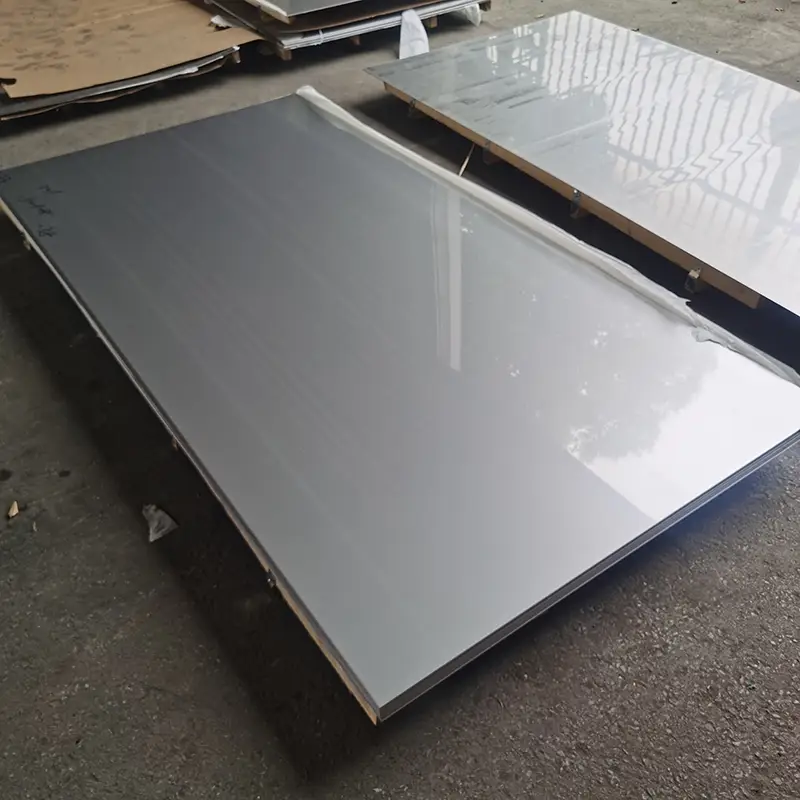

2B, 2D, BA NO (8), Cold rolled sheet (CR), Hot rolled plate (HR), SATIN (Met with Plastic Coated), No.1 finish hot rolled, 1D, 2B, No.4, BA, 8K, satin, hairline, brush, mirror etc. |

|

Hardness |

Half Hard, Soft, Hard, Quarter Hard, Spring Hard |

|

Form |

Sheet, Plate, Strip, Flats, Clad Plate, Coils, Foils, Plain Sheet, Flat Shim, Flat Sheet, Shim Sheet, Rolling Sheet, Rolling Plate, Rolls, Blank (Circle), soft annealed, descaled, tread plate, sheared, annealed, Checker Plate |

|

Value Added Service |

Cladding, Heat Treatment, Annealed, Pickling, Polish, Rolling, Cutting, Bending, Forging, Minor Fabrication Etc. |

|

Stainless Steel 317 / 317L Profiling |

Plasma Plate Cutting |

317L Cold Rolled Plate Sizes

|

SIZE |

SIZE |

|

.125" |

3.18mm |

|

.134" |

3.40mm |

|

.156" |

3.96mm |

|

.187" |

4.75mm |

|

.250" |

6.35mm |

|

.312" |

7.92mm |

|

.375" |

9.53mm |

|

.500" |

12.7mm |

|

.625" |

15.9mm |

|

.750" |

19.1mm |

|

.875" |

22.2mm |

|

1" |

25.4mm |

|

1.125" |

28.6mm |

|

1.250" |

31.8mm |

|

1.500" |

38.1mm |

|

1.750" |

44.5mm |

|

2" |

50.8mm |

|

2.500" |

63.5mm |

|

3" |

76.2mm |

Dimensions of 317L SS Plate

Metric Dimensions

|

Surface finish |

Thickness (mm) |

Width (mm) |

|

2B – Cold rolled, heat treated, pickled, skin passed |

0.25–8.0 |

max. 2032 |

|

2D – Cold rolled, heat treated, pickled |

0.4–6.35 |

max. 1524 |

|

2E – Cold rolled, heat treated, mechanically descaled |

0.4–8.0 |

max. 2032 |

|

2R – Cold rolled, bright annealed |

0.25–3.5 |

max. 1524 |

|

2H – Work hardened |

0.4–6.35 |

max. 1524 |

|

Polished, brushed |

0.5–4.0 |

max. 1524 |

Imperial Dimensions

|

Surface finish |

Gauge (in) |

Width (in) |

|

2B – Cold rolled, heat treated, pickled, skin passed |

10–24 |

max. 72* |

|

2D – Cold rolled, heat treated, pickled |

12–24 |

max. 60 |

|

BA Mexinox only |

18–28 |

max. 48 |

|

Polished (not brushed) |

11–24 |

max. 60 |

|

Temper rolled Mexinox only |

13–29 |

max. 48 |

Chemical Composition

|

Carbon |

Silicon |

Sulfur |

Phosphorus |

Chromium |

Molybdenum |

Manganese |

Nickel |

Nitrogen |

|

0.030 |

0.75 |

0.030 |

0.045 |

18.0-20.0 |

3.0-4.0 |

2.00 |

11.0-15.0 |

0.10 |

Mechanical Properties

|

Yield Strengtd |

Ultimate Tensile |

Elongation |

Hardness |

||

|

psi (min.) |

(MPa) |

psi (min.) |

(MPa) |

% (min.) |

(max.) |

|

30,000 |

205 |

75,000 |

515 |

40 |

95 Rockwell B |

Physical Properties

|

Density lb/inᶟ |

0.285 |

|

Density g/cmᶟ |

7.89 |

|

Melting Range |

2540-2630°F/1390 – 1440 °C |

|

Thermal Conductivity at 212°F (100°C) |

8.7 BTU/hr/ft²/ft/°F |

|

Thermal Conductivity at 212°F (100°C) |

1.26 W/m-°K |

|

Electrical Resistivity |

33.5 Microhm-in at 68°C |

|

Electrical Resistivity |

85.1 Microhm-cm at 20°C |

Equivalent Grades

|

STANDARD |

UNS |

WNR. |

JIS |

EN |

|

SS 317 |

S31700 |

1.4449 |

SUS 317 |

- |

|

SS 317L |

S31703 |

1.4438 |

SUS 317L |

X2CrNiMo18-15-4 |

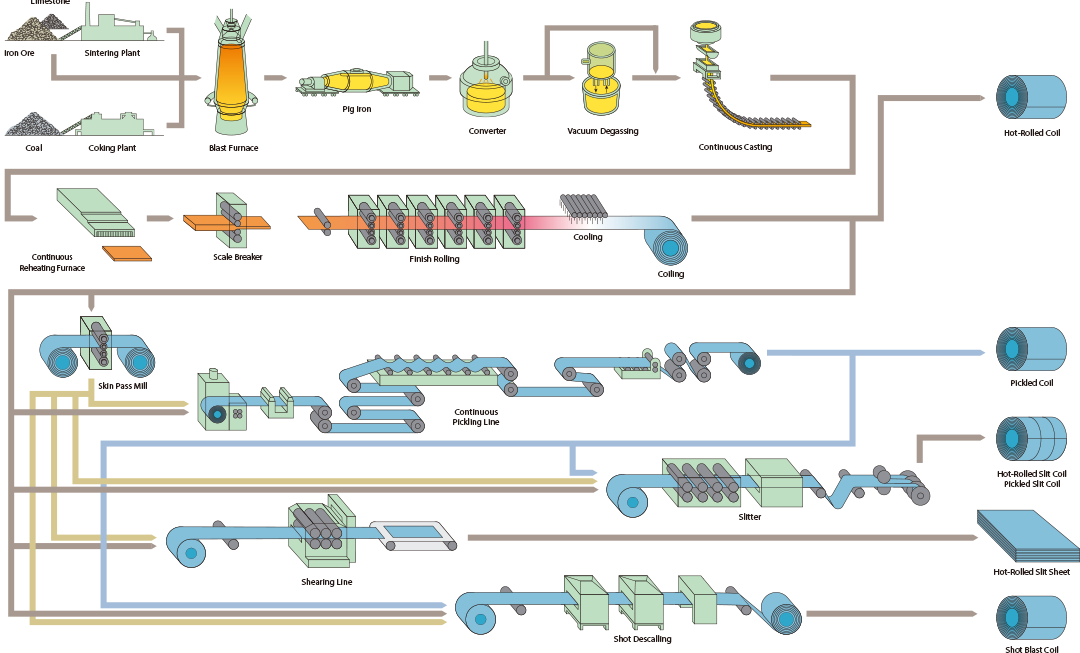

Hot-Rolled Steel Sheets and Coils

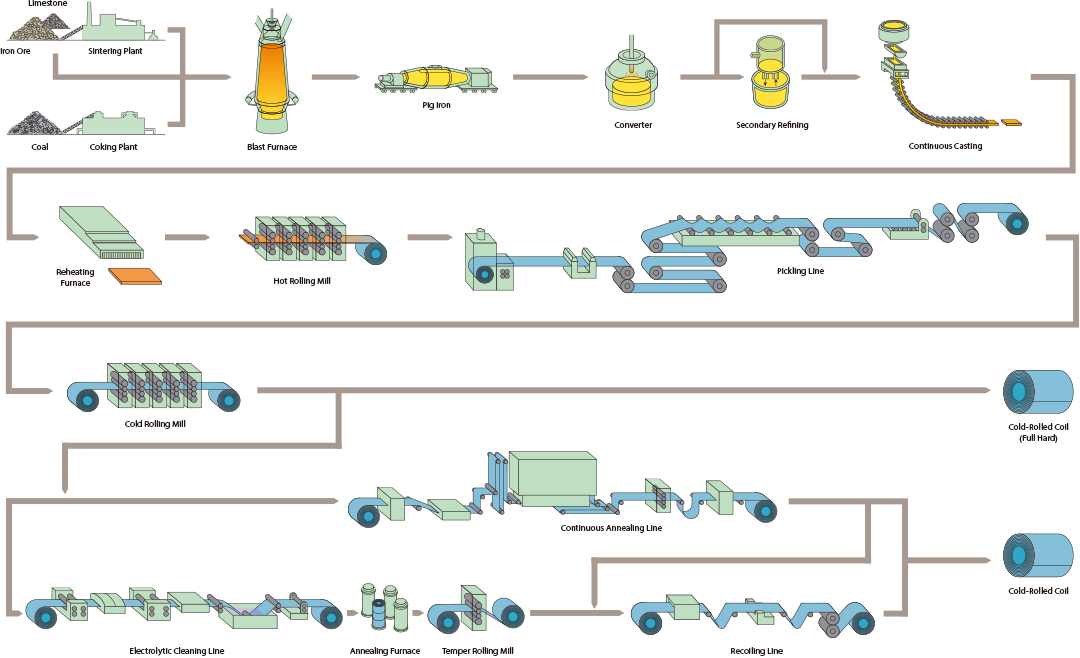

Cold-Rolled Steel Sheets and Coils