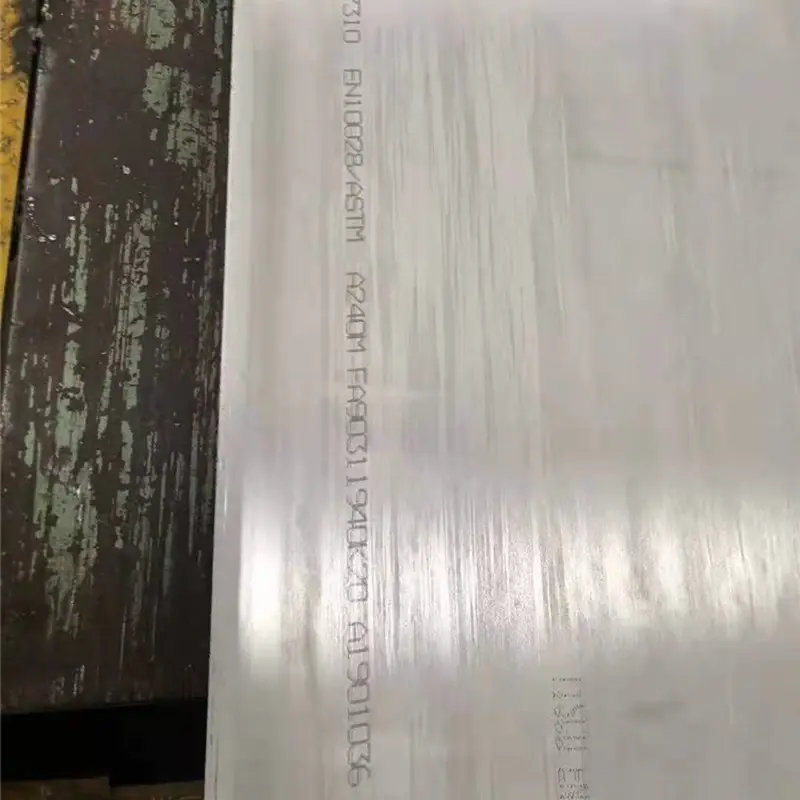

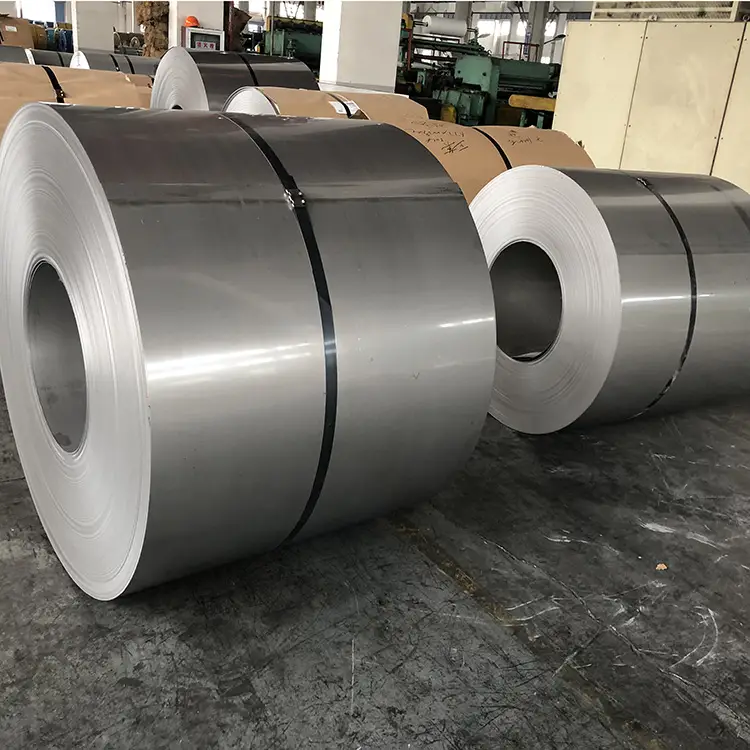

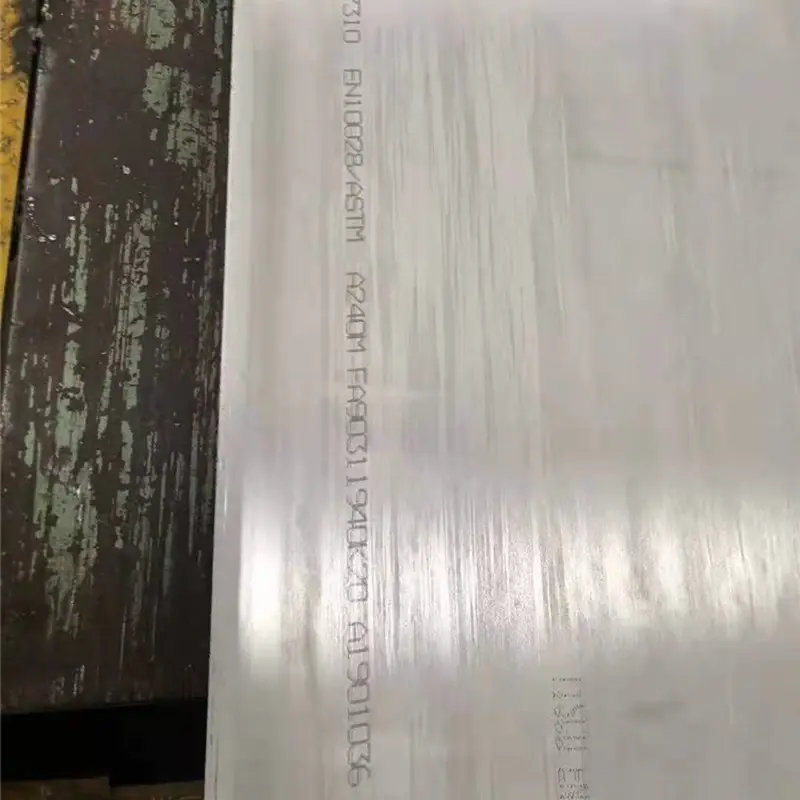

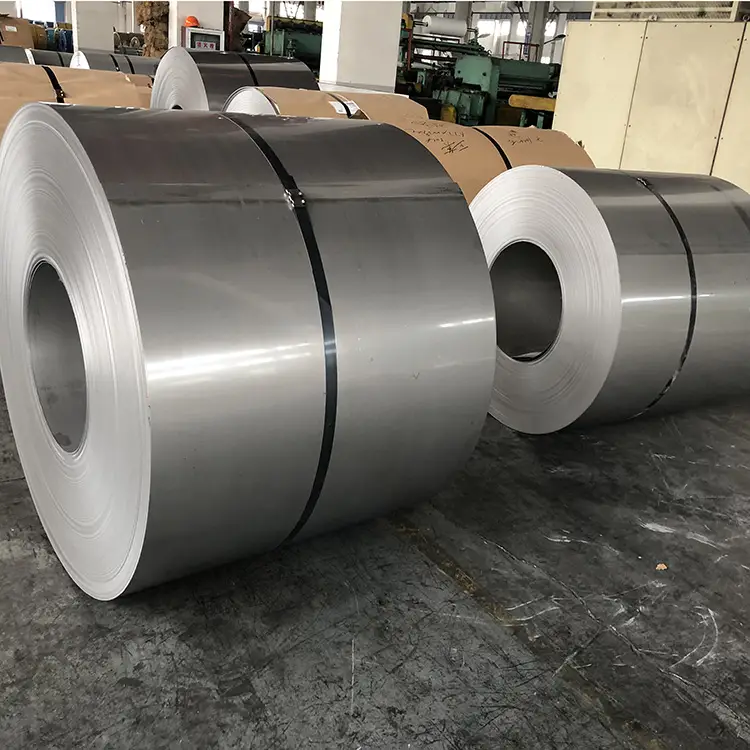

carbon steel plate,steel coil,stainless steel plate,china export service provider.

carbon steel plate,steel coil,stainless steel plate,china export service provider.

Alloy 2304 is a 23% chromium, 4% nickel, molybdenum-free duplex stainless steel. The Alloy 2304 has corrosion resistance properties similar to 316L. Furthermore, its mechanical properties, i.e., yield strength, are twice those of 304L/316L austenitic grades. This allows the designer to save weight, particularly for properly designed pressure vessel applications.

The alloy is particularly suitable for applications covering the -50°C/+300°C (-58°F/572°F) temperature range. Lower temperatures may also be considered but need some restrictions, particularly for welded structures.

With its duplex microstructure and low nickel and high chromium contents, the alloy has improved stress corrosion resistance properties compared to 304 and 316 austenitic grades.

2304 Duplex Stainless Steel Applications:

Duplex 2304 is generally used in the same applications in which Alloys 304 and 316L are used. Some examples of these applications include:

Chloride containing environments

Welded pipe systems within the Pulp and Paper, Chemical and Petrochemical, and Water Treatment industries

Transportations

Heat exchanger tubes

Architecture, building, construction

Pressure vessels

Caustic solutions, organic acids

Food industry

Equivalent Standards of 2304 Duplex Stainless Steel:

ASTM/ASME: UNS S32304

EURONORM: FeMi35Cr20Cu4Mo2

DIN: 2.4660

|

Property |

Value |

|

Length |

3000 - 6000 mm

|

|

Thickness |

2 - 50 mm

|

|

Width |

1500 - 2000 mm

|

Composition

|

|

C |

Cr |

Fe |

Mn |

Si |

S |

P |

Ni |

Cu |

N |

|

Duplex |

0.03 |

min: 21.5 |

Bal. |

2.5 |

1.0 |

0.03 |

0.04 |

min:3.0 max:3.5 |

min:0.05 |

min: 0.05 |

Mechanical Properties

|

Grade |

Tensile Strength ksi (MPa) |

Yield Strength 0.2% offset ksi (MPa) |

Elongation (% in 50mm) min |

Hardness (Brinell) |

Hardness |

|

Duplex 2304 |

87 |

58 |

25 |

293 |

31^j |

Physical Properties

|

|

Duplex 2304 |

|

Density at 68°F (20°C) |

0.28 lbm/in3 |

|

Coefficient of Thermal Expansion |

ax10-6°C-1 |

|

68°F to: 212°F |

13 |

|

68°F to 392°F |

13.5 |

|

68°F to 572°F |

14 |

|

Thermal Conductivity |

W.m-1.K-1 |

|

at 68°F(20°C) |

17 |

|

at 212°F(100°C) |

18 |

|

at 392°F(200°C) |

19 |

|

at 572°F(300°C) |

20 |

|

Electrical Resitivity |

(µ_ cm) |

|

at 68°F(20°C) |

80 |

|

at 212°F(100°C) |

92 |

|

at 392°F(200°C) |

100 |

|

at 572°F(300°C) |

105 |

|

Specific Heat |

(Btu/lb/°F) |

|

32°F to: 212°F |

0.11 |

Hot Forming

Hot forming must be performed in the 1150/900°C (2100/1650°F) temperature range. After forming, a new solution annealing treatment is recommended in the 950°/1050°C (2100°/1650°F) temperature range to fully restore corrosion resistance properties and mechanical properties. Parts formed with 2304 must be supported carefully during heating to avoid creep deformation.

Cold Forming

Alloy 2304 may be cold formed without any problem. The same equipment as used for the cold forming of 304L and 316L grades can be used. Due to its higher mechanical properties, including the yield strength, higher stresses are required for cold forming. A final solution annealing heat treatment is also recommended after cold forming in order to restore the mechanical and corrosion resistance properties, as decribed in ‘hot forming.’

Descaling

Use the same solutions and pastes as for Alloys 304L/316L. The pickling time will be higher than for austenitic grades due to the corrosion resistance properties of the alloy.

Machinability

Alloy 2304 duplex exhibits improved machinability properties particularly when considering drilling. Its behavior is equivalent to that of 316LEZ*. Furthermore, 2304 has better corrosion resistance and cleanliness properties as no sulphur additions are necessary. Localized corrosion resistance behavior is improved.