carbon steel plate,steel coil,stainless steel plate,china export service provider.

carbon steel plate,steel coil,stainless steel plate,china export service provider.

In most instances the corrosion resistance of Alloy 316H will be comparable to Alloy 316/316 L and will have superior corrosion resistance to Alloy 304/304L. Process environments that do not attack Alloy 304/304L will not attack this grade. One exception, however, is in highly oxidizing acids such as nitric acid where stainless steels containing molybdenum are less resistant. Alloy 316H performs well in sulfur containing service such as that encountered in the pulp and paper industry. The alloy can be used in high concentrations at temperatures up to 120°F (38°C).

Alloy 316H also has good resistance to pitting in phosphoric and acetic acids. It performs well in boiling 20% phosphoric acid. The alloy can also be used in food and pharmaceutical process industries where it is utilized to handle hot organic and fatty acids where product contamination is a concern.

Alloy 316H performs well in fresh water service even with high levels of chlorides. The alloy has excellent resistance to corrosion in marine environments under atmospheric conditions.

The higher molybdenum content of Alloy 316H assures it will have superior pitting resistance to Alloy 304/304L in applications involving chloride solutions particularly in oxidizing environments.

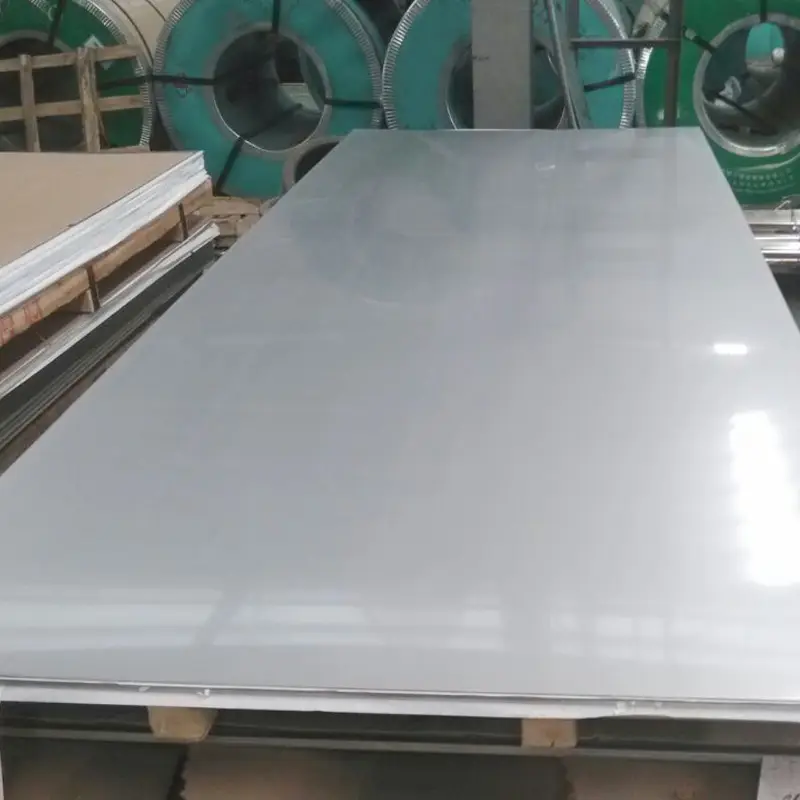

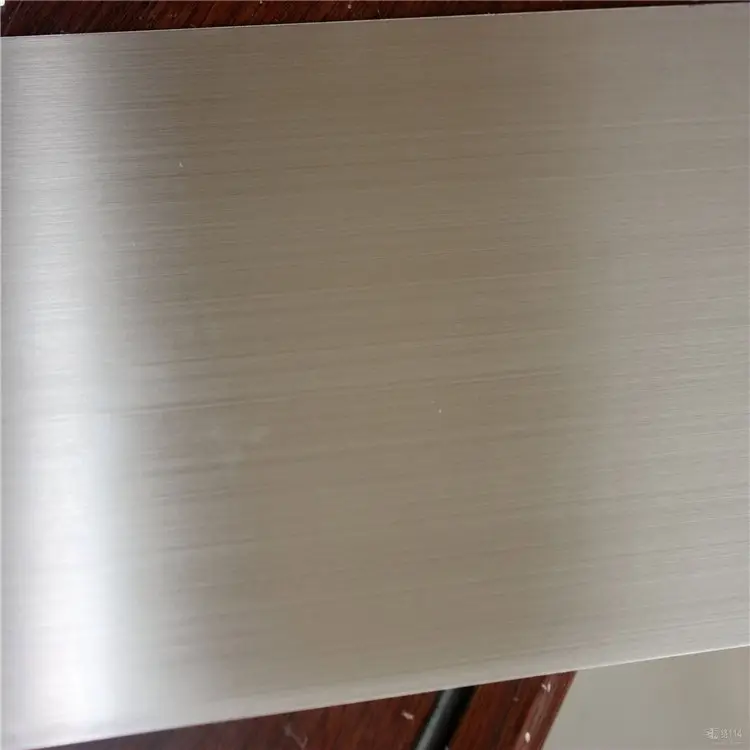

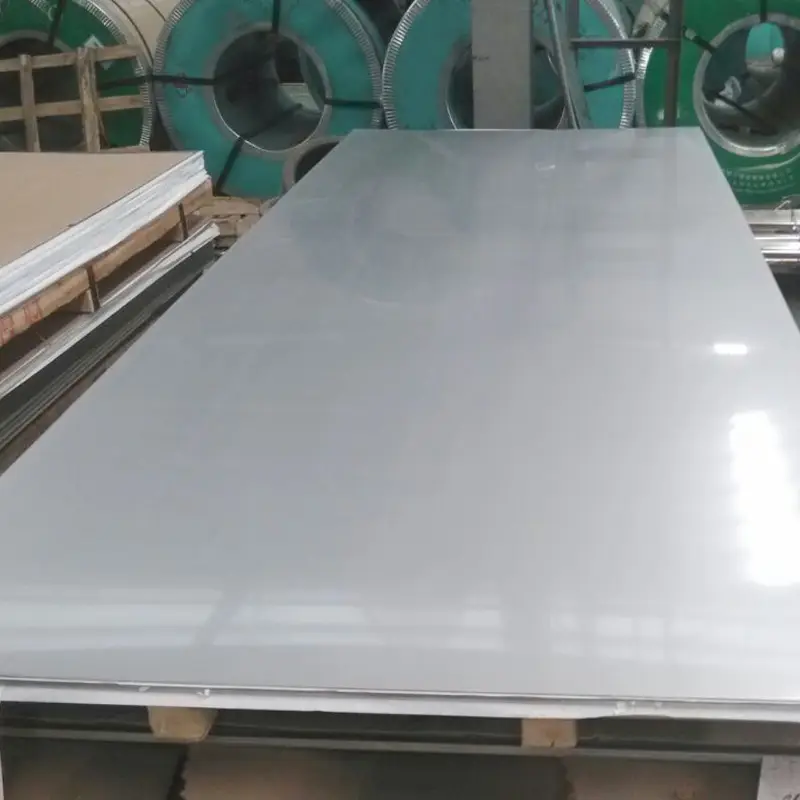

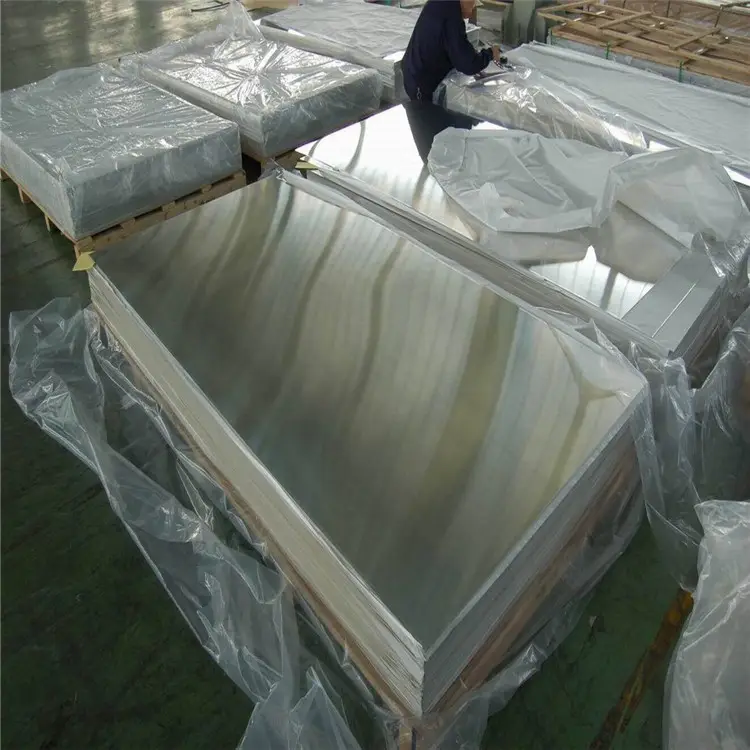

316H Stainless Steel Sheet Finish/ Plate Finish

No. 2D - A smooth, non-reflective cold-rolled annealed and pickled or descaled finish.

No. 2B - A smooth, moderately reflective cold-rolled annealed and pickled or descaled finish typically produced by imparting a final light cold-rolled pass using [large diameter] polished rolls.

Bright Annealed [BA] Finish- A smooth, bright, reflective finish typically produced by cold rolling followed by annealing in a protective atmosphere so as to prevent oxidation and scaling during annealing.

No. 3 Finish is characterized by short, coarse, parallel polishing lines, which extend uniformly along the length of the coil.

No.4 Finish is characterized by short, parallel polishing lines, which extend uniformly along the length of the coil. It is obtained by mechanically polishing a No. 3 finish with gradually finer abrasives.

No.7 Finish has a high degree of reflectivity and a mirror-like appearance. A No. 4 finish that has been polished to 320-grit is buffed for up to 10 minutes but existing grit lines are not removed. The remnants of fine polishing lines can generally seen by an observer standing several feet from a panel.

No.8 Finish It is produced in the same manner as the No. 7 finish except that the buffing is continued for an additional five to ten minutes. In comparison to a No. 7 finish, the grit lines are much less visible, but they can be seen if the finish is examined closely. The resulting finish is mirror-like but not a perfect mirror.

|

|

Thickness (mm) |

||||||||||||

|

0.3 |

0.4 |

0.5 |

0.6 |

0.7 |

0.8 |

0.9 |

1.0 |

1.2 |

1.5 |

2.0 |

3.0 |

||

|

Grade |

Dimension (mm) |

Weight (kg/sheet) |

|||||||||||

|

316H |

1000 x 2000 |

4.76 |

6.34 |

7.93 |

9.52 |

11.1 |

12.7 |

14.3 |

15.9 |

19.0 |

23.8 |

31.7 |

47.6 |

|

1219 x 2438 (4’ x 8’) |

7.07 |

9.43 |

11.8 |

14.1 |

16.5 |

18.9 |

21.2 |

23.6 |

28.3 |

35.4 |

47.1 |

70.7 |

|

|

1250 x 2500 |

7.43 |

9.91 |

12.4 |

14.9 |

17.3 |

19.8 |

22.3 |

24.8 |

29.7 |

37.2 |

49.6 |

74.3 |

|

|

1524 x 3048 (5’ x 10’) |

11.1 |

14.7 |

18.4 |

22.1 |

25.8 |

29.5 |

33.2 |

36.8 |

44.2 |

55.3 |

73.3 |

110.5 |

|

|

430 |

1000 x 2000 |

4.62 |

6.16 |

7.70 |

9.24 |

10.8 |

12.3 |

13.9 |

15.4 |

18.5 |

23.1 |

30.8 |

46.2 |

|

1219 x 2438 (4’ x 8’) |

6.87 |

9.15 |

11.4 |

13.7 |

16.0 |

18.3 |

20.6 |

22.9 |

27.5 |

34.3 |

45.8 |

68.7 |

|

|

1250 x 2500 |

7.22 |

9.63 |

12.0 |

14.4 |

16.8 |

19.3 |

21.7 |

24.1 |

28.9 |

36.1 |

48.1 |

72.2 |

|

Equivalent Grades

|

STANDARD |

UNS |

WNR. |

AFNOR |

EN |

JIS |

BS |

GOST |

|

SS 316 |

S31600 |

1.4401 / 1.4436 |

Z7CND17‐11‐02 |

X5CrNiMo17-12-2 / X3CrNiMo17-13-3 |

SUS 316 |

316S31 / 316S33 |

- |

|

SS 316L |

S31603 |

1.4404 / 1.4435 |

Z3CND17‐11‐02 / Z3CND18‐14‐03 |

X2CrNiMo17-12-2 / X2CrNiMo18-14-3 |

SUS 316L |

316S11 / 316S13 |

03Ch17N14M3 / 03Ch17N14M2 |

|

SS 316L |

S31609 |

1.4401 |

- |

- |

SUS 316H |

- |

- |

Chemical Composition

|

Grade |

C |

Mn |

Si |

P |

S |

Cr |

Mo |

Ni |

Fe |

|

SS 316H |

0.10 max |

2.0 max |

0.75 max |

0.045 max |

0.030 max |

16 – 18 |

2 - 3 |

10 – 14 |

68.89 min |

Mechanical Properties

|

Density |

Melting Point |

Tensile Strength |

Yield Strength (0.2%Offset) |

Elongation |

|

8.0 g/cm3 |

1400 °C (2550 °F) |

Psi – 75000 , MPa – 515 |

Psi – 30000 , MPa – 205 |

35 % |

Physical Properties for SS 316 H Plates

|

Grade |

Density (kg/m3) |

Elastic Modulus (GPa) |

Mean Coefficient of Thermal Expansion (μm/m/°C) |

Thermal Conductivity (W/m.K) |

Specific Heat 0-100°C (J/kg.K) |

Electrical Resistivity (nΩ.m) |

|||

|

0-100°C |

0-315°C |

0-538°C |

at 100°C |

at 500°C |

|||||

|

316 H |

8000 |

193 |

15.9 |

16.2 |

17.5 |

16.3 |

21.5 |

500 |

740 |

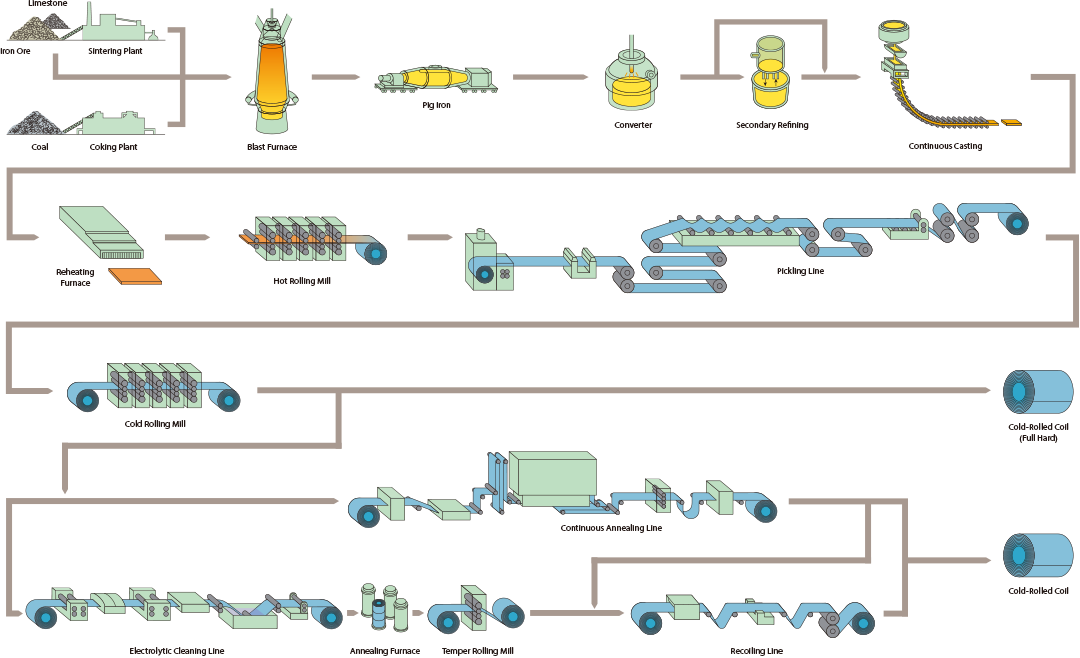

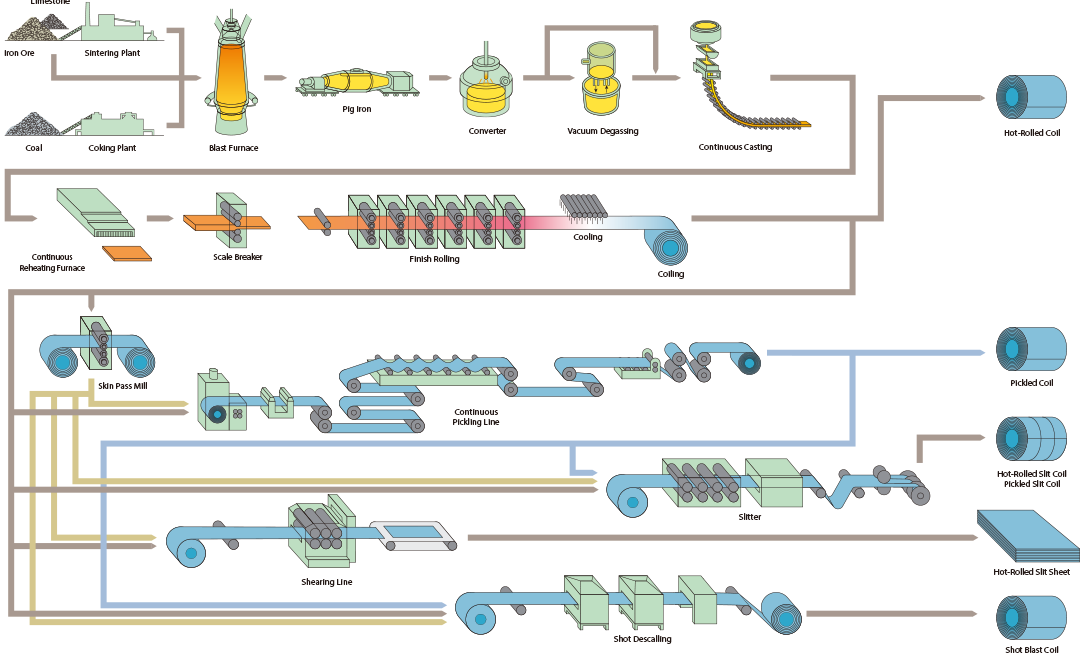

Hot-Rolled Steel Sheets and Coils

Cold-Rolled Steel Sheets and Coils