carbon steel plate,steel coil,stainless steel plate,china export service provider.

carbon steel plate,steel coil,stainless steel plate,china export service provider.

317 l (00 cr19ni13mo3, UNS S31726) alloy is based on molybdenum austenitic stainless steel. It with conventional chrome - nickel austenitic stainless steel, such as, compared to 304 alloy has the stronger ability of resistance to chemical corrosion. In addition, compared with the conventional stainless steel, 317 l alloy has higher ductility, resistance to stress corrosion performance, compressive strength and resistance to high temperature performance. It is a low carbon level or L level, this level has during the welding and heat treatment process the sensitization effect of resistance.

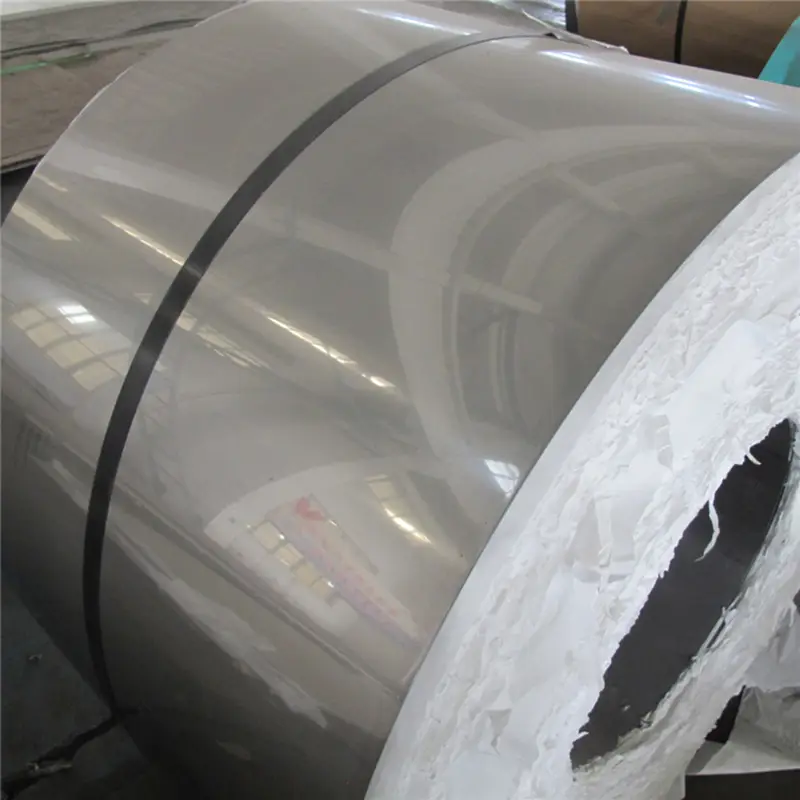

ASTM A240 317 317L Stainless Steel Coil

ASTM A240 standard specification for chromium and chromium-nickel stainless steel plate, sheet, and strip for pressure vessels and for general applications

A240 grade 800 800H 904L 201 202 XM-19 XM-31 XM-17 XM-18 XM-19 301 301L 302 304 304L 304H 304N XM-21 304LN 305 309S 309H 309Cb 309HCb 310S 310H 310Cb 310HCb 310MoLN 316 316L 316H 316Ti 316Cb 316N 316LN 317 317l 317LM 317LMN 317LN 321 321H 334 347 347H 348 348H XM-15 2205 2304 255 2507 329 405 409 410 410S 429 430 439 434 436 444 XM-33 XM-27

Surface Finished Of Stainless Steel Coil

|

Surface finish |

Characteristics & Application |

|

NO 1 |

Hot-rolled surface,annealed and pickled,can be used as cold-rolling material,industial tanks and chem i cal devices. |

|

2D |

Cold-rolled, an nealed and pick led with out skinpassing the dull prod ucts can be used as auto mo bile parts, build ing materrials and pipings. |

|

2B |

The surface brightness and flatness of NO.2B is better than NO.2D. Then through a special surfacetreament to improve its mechamical properties, N02B could nearly satisfy com pre hen sive uses. |

|

NO.3 |

Polished with abra sive belt of grit #100#120,have bet ter bright ness with dis con tin u ous coarse stria, used as in ner and ex ter nal or na ments for building, elec tri cal ap pli anc es and kitchen uten sils etc. |

|

NO.4 |

Polished with abrasive belt of grit #150#180, have better brightness with discontinuous coarse stria, but thinner than NO.3, are used as bathtud buildinginner and external ornaments electrical appliances, kitchen utensils and food processing equipment etc. |

|

#320 |

Polished with abrasive belt of grit #320, have better brightness with discontinuous coarse stria, but thinner NO.3, are used as bathtub building inner and external ornaments electrical appliances kitchen utensils and food lprocessing equipment etc. |

|

HL |

Polished with abrasive belt of grit #150-320 on the No.4 finish and has continuous streaks, mainly used as building ornaments, elevators, door of building, frontal plate etc. |

|

BA |

Cold rolled, bright an nealed and skin-passed, the prod uct has ex cel lent bright ness and good re flex iv i ty like mirror, used for lectrical appliances, mirror, kitch en apparatus, or na ment ma te ri als etc |

|

Standard |

ASTM A240 / ASME SA240 etc |

|

Production |

Hot-Rolled (HR) / Cold-Rolled (CR) |

|

Thickness |

1.0mm – 100 mm |

|

Width |

1000 mm-2000 mm |

|

Length |

1000 mm – 6000 mm |

Size (in mm)

Thickness

Specification

1000 x 2000

0.3 mm To 120 mm

ASTM A240 / ASME SA240, JIS4304-2005, ASTM A167, EN10088-2-2005, GB/T3280-2007, etc

1220 x 2440

(4′ x 8′)

1250 x 2500

1500 x 3000 To 6000

2000 x 4000 To 6000

Chemical Composition

|

Carbon |

Silicon |

Sulfur |

Phosphorus |

Chromium |

Molybdenum |

Manganese |

Nickel |

Nitrogen |

|

0.030 |

0.75 |

0.030 |

0.045 |

18.0-20.0 |

3.0-4.0 |

2.00 |

11.0-15.0 |

0.10 |

Mechanical Properties

|

Yield Strengtd |

Ultimate Tensile |

Elongation |

Hardness |

||

|

psi (min.) |

(MPa) |

psi (min.) |

(MPa) |

% (min.) |

(max.) |

|

30,000 |

205 |

75,000 |

515 |

40 |

95 Rockwell B |

Physical Properties

|

Density lb/inᶟ |

0.285 |

|

Density g/cmᶟ |

7.89 |

|

Melting Range |

2540-2630°F/1390 – 1440 °C |

|

Thermal Conductivity at 212°F (100°C) |

8.7 BTU/hr/ft²/ft/°F |

|

Thermal Conductivity at 212°F (100°C) |

1.26 W/m-°K |

|

Electrical Resistivity |

33.5 Microhm-in at 68°C |

|

Electrical Resistivity |

85.1 Microhm-cm at 20°C |

Equivalent Grades

|

STANDARD |

UNS |

WNR. |

JIS |

EN |

|

SS 317 |

S31700 |

1.4449 |

SUS 317 |

- |

|

SS 317L |

S31703 |

1.4438 |

SUS 317L |

X2CrNiMo18-15-4 |

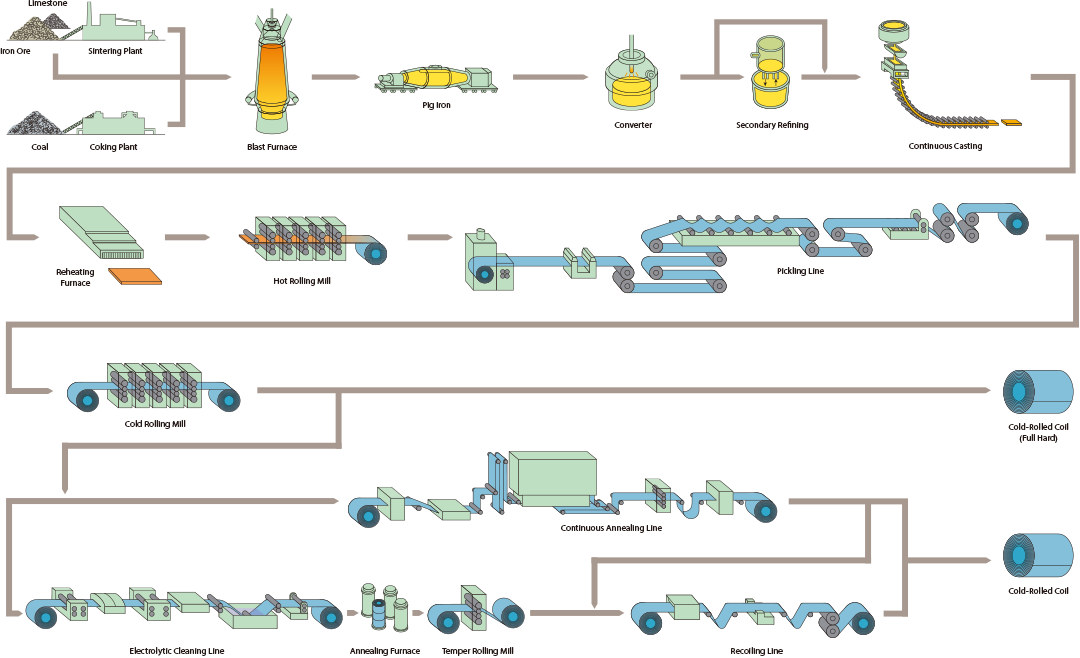

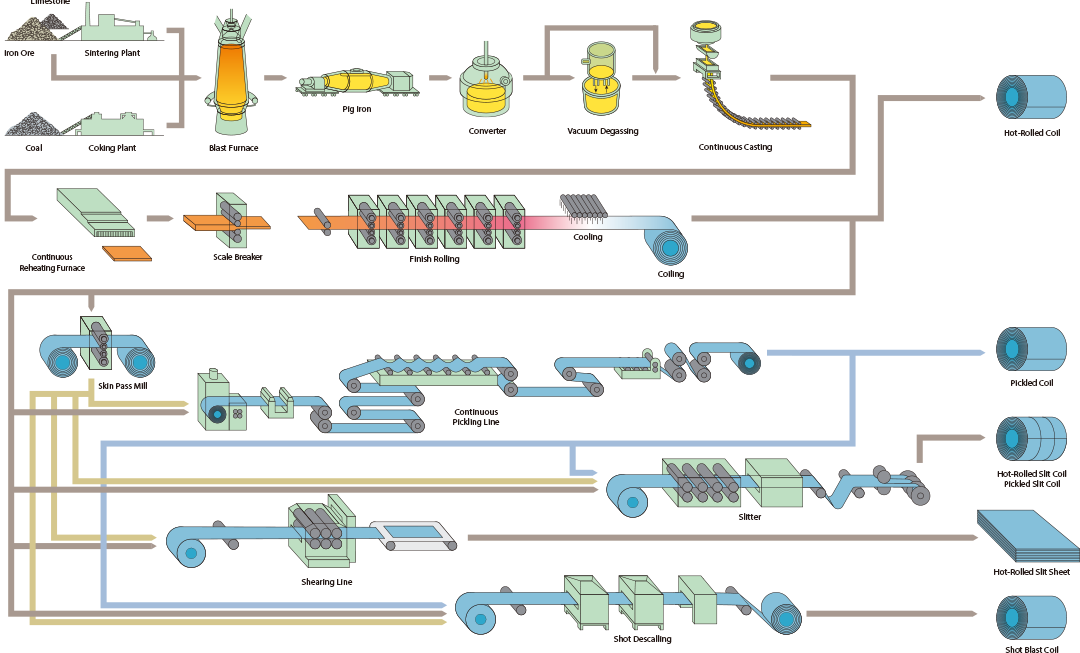

Hot-Rolled Steel Sheets and Coils

Cold-Rolled Steel Sheets and Coils