carbon steel plate,steel coil,stainless steel plate,china export service provider.

carbon steel plate,steel coil,stainless steel plate,china export service provider.

347 stainless steel are austenitic stainless steels that contain stabilizing elements. This alloys is easily welded. Annealing may not be required after welding unless stress relief is desired. 347 stainless steel has excellent resistance to oxidation and corrosion. With high creep strength, 347 stainless steel work best up to 1600 °F. The addition columbium plus tantalum in 347 stainless steel give some desired characteristics like:

(1)Prevents harmful carbide precipitation in the heat affected zone (HAZ) of the weld area

(2)Imparts substantial immunity to intergranular corrosion

(3)Reduced embrittlement in the HAZ of the weld area

347H stainless steel plate is a very stable stainless steel. When the temperature reaches 800-1500 ° F (427-816 ° C) and chromium carbide precipitates, it can still maintain good resistance to intergranular corrosion. Due to the addition of titanium to the composition, 347H can still maintain stability in the case of chromium carbide formation. 347H stainless steel has advantages in working under high temperature due to its excellent mechanical properties. Compared with 304, 347H stainless steel has better ductility and resistance to stress fracture.

Candidates are also important in many cases. For example, if ordinary stainless steel (such as 304) is used instead of special stainless steel in daily use in a high temperature or high corrosion environment, ordinary stainless steel (304) is not suitable for this. High temperature oxidation.

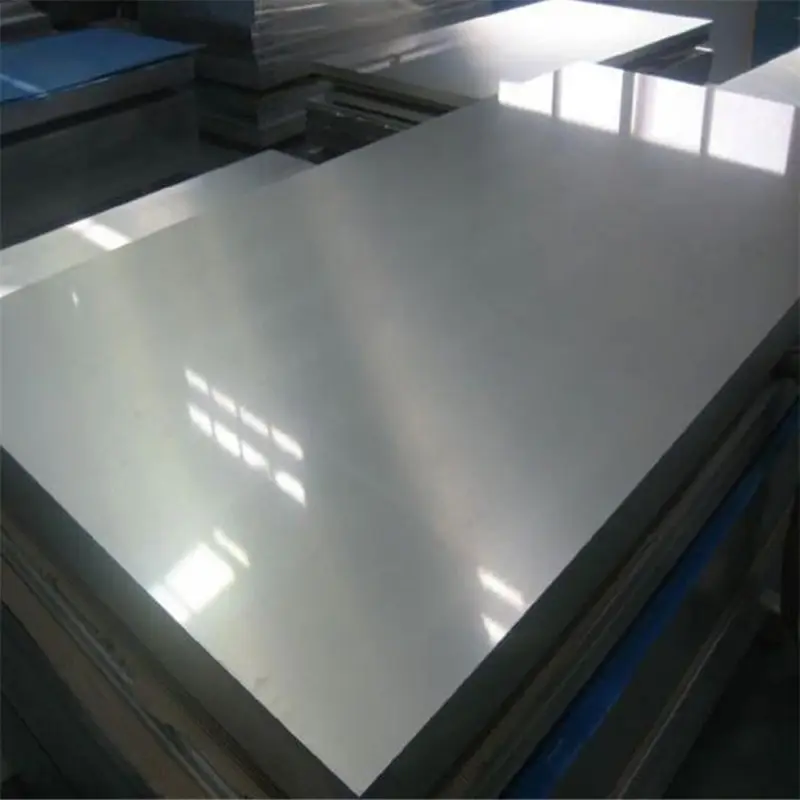

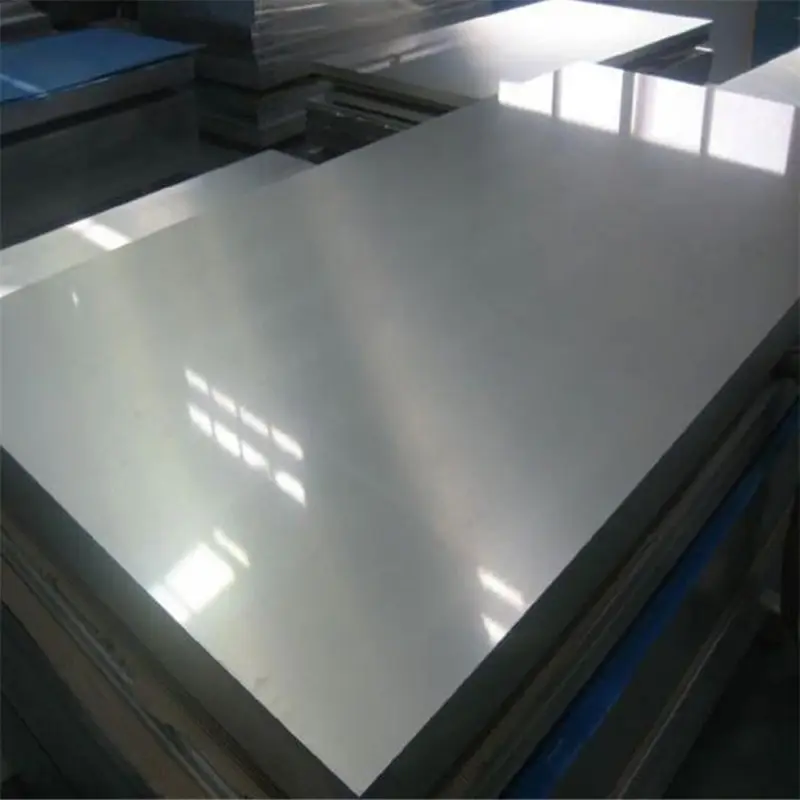

Finishes Of Stainless Steel 347 / 347H Sheets & Plates

|

Surface Finish |

Definition |

Application |

|

2B |

Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. |

Medical equipment, Food industry, Construction material, Kitchen utensils. |

|

BA |

Those processed with bright heat treatment after cold rolling. |

Kitchen utensils, Electric equipment, Building construction. |

|

NO.3 |

Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. |

Kitchen utensils, Building construction. |

|

NO.4 |

Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. |

Kitchen utensils, Building construction, Medical equipment. |

|

HL |

Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. |

Building Construction. |

|

NO.1 |

The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. |

Chemical tank, pipe |

|

Stainless Steel Gauge Width and Length |

Weight Lbs. per Sq. Ft. |

Estimated Weight per Sheet |

|

7 ga. (.1874") x 48 x 120 |

7.871 |

314.8 |

|

10 ga. (.135") x 48 x 120 |

5.670 |

226.8 |

|

11 ga. (.120") x 36 x 120 |

5.040 |

151.2 |

|

11 ga. (.120") x 48 x 96 |

5.040 |

161.3 |

|

11 ga. (.120") x 48 x 120 |

5.040 |

201.6 |

|

11 ga. (.120") x 48 x 144 |

5.040 |

241.9 |

|

11 ga. (.120") x 60 x 96 |

5.040 |

252.0 |

|

12 ga. (.105") x 36 x 120 |

4.410 |

132.3 |

|

12 ga. (.105") x 48 x 120 |

4.410 |

176.4 |

|

12 ga. (.105") x 60 x 120 |

4.410 |

220.5 |

|

14 ga. (.075") x 36 x 120 |

3.150 |

94.50 |

|

14 ga. (.075") x 48 x 120 |

3.150 |

126.0 |

|

16 ga. (.060") x 36 x 120 |

2.520 |

75.60 |

|

16 ga. (.060") x 48 x 96 |

2.520 |

80.64 |

|

16 ga. (.060") x 48 x 120 |

2.520 |

100.8 |

|

16 ga. (.060") x 60 x 120 |

2.520 |

126.0 |

|

18 ga. (.048") x 36 x 120 |

2.016 |

60.48 |

|

18 ga. (.048") x 48 x 120 |

2.016 |

80.64 |

|

20 ga. (.036") x 36 x 120 |

1.512 |

45.36 |

|

20 ga. (.036") x 48 x 120 |

1.512 |

60.48 |

|

22 ga. (.030") x 36 x 120 |

1.260 |

37.80 |

|

22 ga. (.030") x 48 x 96 |

1.260 |

40.32 |

|

22 ga. (.030") x 48 x 120 |

1.260 |

50.40 |

|

24 ga. (.024") x 36 x 120 |

1.008 |

30.24 |

|

24 ga. (.024") x 48 x 120 |

1.008 |

40.32 |

|

26 ga. (.018") x 36 x 120 |

.7560 |

22.68 |

|

26 ga. (.018") x 48 x 120 |

.7560 |

30.24 |

|

28 ga. (.015") x 36 x 120 |

.6300 |

18.90 |

EQUIVALENT GRADES

|

STANDARD |

WERKSTOFF NR. |

UNS |

JIS |

GOST |

EN |

|

SS 347 |

1.4550 |

S34700 |

SUS 347 |

08Ch18N12B |

X6CrNiNb18-10 |

|

SS 347H |

1.4961 |

S34709 |

SUS 347H |

- |

X6CrNiNb18-12 |

CHEMICAL COMPOSITION

|

Grade |

C |

Mn |

Si |

P |

S |

Cr |

Cb |

Ni |

Fe |

|

347 |

0.08 max |

2.0 max |

1.0 max |

0.045 max |

0.030 max |

17.00 - 20.00 |

10xC – 1.10 |

9.00 - 13.00 |

62.74 min |

|

347H |

0.04 – 0.10 |

2.0 max |

1.0 max |

0.045 max |

0.030 max |

17.00 - 19.00 |

8xC – 1.10 |

9.0 -13.0 |

63.72 min |

MECHANICAL PROPERTIES

|

Density |

Melting Point |

Tensile Strength |

Yield Strength (0.2%Offset) |

Elongation |

|

8.0 g/cm3 |

1454 °C (2650 °F) |

Psi – 75000 , MPa – 515 |

Psi – 30000 , MPa – 205 |

35 % |

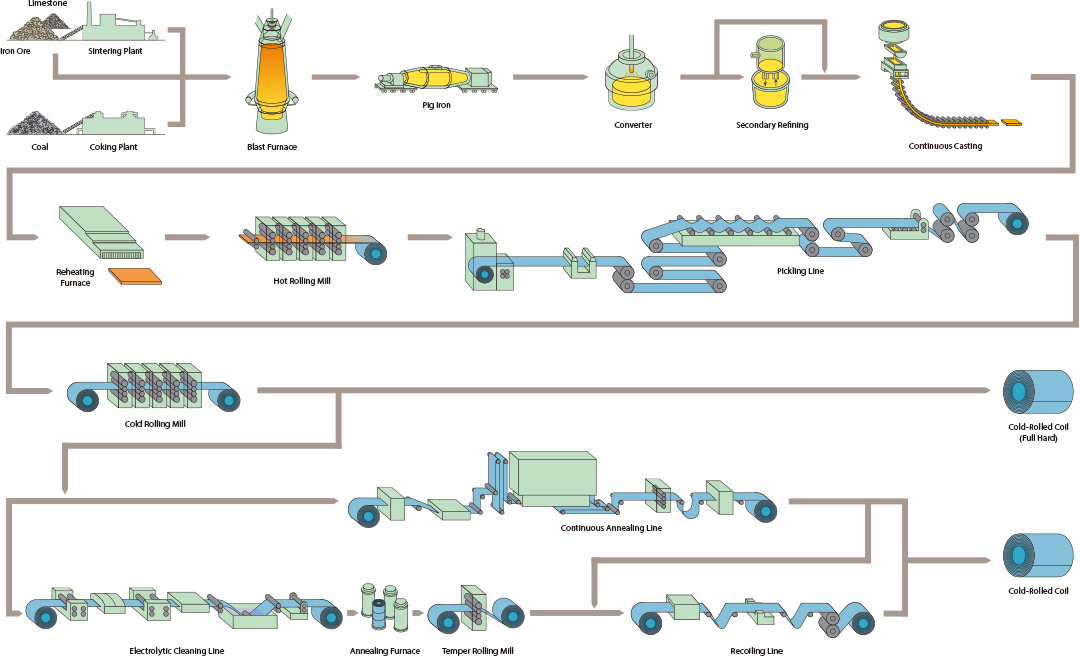

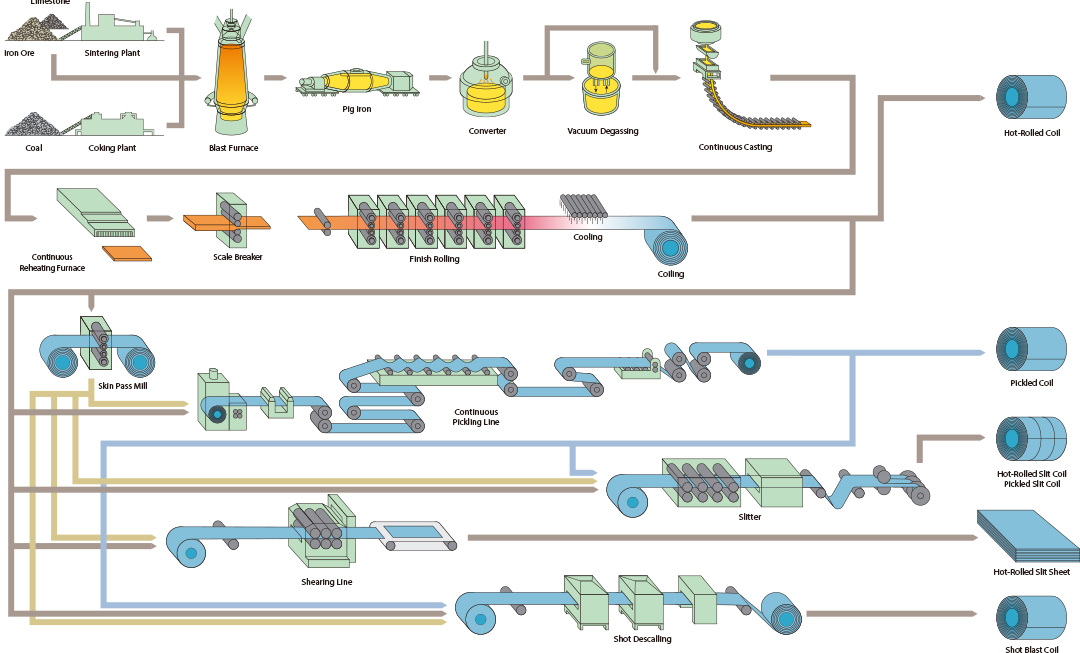

Hot-Rolled Steel Sheets and Coils

Cold-Rolled Steel Sheets and Coils