carbon steel plate,steel coil,stainless steel plate,china export service provider.

carbon steel plate,steel coil,stainless steel plate,china export service provider.

Alloy 410 stainless steel plate is the general purpose 12% chromium martensitic stainless steel that can be heat treated to obtain a wide range of mechanical properties. 410 stainless steel plate possesses high strength and hardness coupled with good corrosion resistance. Alloy 410 stainless steel plate is ductile and can be formed. It is magnetic in all conditions.

Alloy 410 (UNS S41000) is a 12% chromium martensitic stainless steel plate that can be heat treated to obtain a wide range of mechanical properties. The alloy has good corrosion resistance along with high strength and hardness. In the annealed condition, 410 stainless steel plate is ductile and may be formed. It remains magnetic in both the annealed and heat treated conditions.

Alloy 410S (UNS S41008) is a low carbon, non–hardening modification of Alloy 410 (UNS S41000) the general purpose 12% chromium martensitic stainless steel. The low carbon and a small alloy addition minimize austenite formation at high temperatures which restricts the alloys ability to harden. 410S remains soft and ductile even when rapidly cooled from above the critical temperature. This non-hardening characteristic helps prevent cracking when the alloy is exposed to high temperatures or welded. 410S is completely ferritic in the annealed condition. It exhibits adequate corrosion resistance similar to 410 and good oxidation resistance.

Heat Treatment

Annealing – Heat slowly to 1500 – 1650°F (816 – 899°C), cool to 1100oF (593°C) in furnace, air cool

Process Annealing – Heat to 1350 – 1450°F (732 – 788°C), air cool

Hardening – Heat to 1700 – 1850°F (927 – 1010°C), air cool or oil quench. Follow by stress-relief or temper

Stress Relieving – Heat to 300 – 800°F (149 – 427°C) for 1 to 2 hours, air cool

Tempering – Heat to 1100 – 1400°F (593 – 760°C) for 1 to 4 hours, air cool

Cold Forming

The alloy can be cold worked with moderate forming in the annealed condition.

Hot Forming

It is typically done in the 1382 – 2102°F (750 – 1150°C) range followed by air cooling. For smaller plate deformation such as bending, preheating should be done in the 212 – 572°F (100 – 300°C) temperature range. If a plate undergoes substantial deformation it should undergo a re-anneal or stress-relieving treatment at about 1202°F (650°C).

Machining

Alloy 410 stainless steel plate is best machined in the annealed condition at surface speeds of 60 – 80 feet (18.3 – 24.4m) per minute. Post machining decontamination and passivation are recommended.

Welding

Alloy 410 stainless steel plate is best machined in the annealed condition at surface speeds of 60 – 80 feet (18.3 – 24.4m) perDue to its martensitic structure, Alloy 410 stainless steel plate has limited weldability because of its hardenability. A post-weld heat treatment should be considered to assure the attainment of the required properties. When weld filler is needed, AWS E/ER 410, 410 NiMo and 309L are the most widely specified.minute. Post machining decontamination and passivation are recommended.

|

Grades |

Stainless Steel J1, J2, J4, 201, 202, 301, 304, 304H, 304L, 309, 309S, 310, 310S, 316, 316L, 316Ti, 321, 321H, 347, 409, 410, 410S, 420, 430, 441, 904L |

|

Thickness |

0.3 mmThk To 10 mm Thk |

|

Width |

1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc |

|

Length |

2000mm, 2440mm, 3000mm, 5800mm, 6000mm, AS PER CUSTOMER’S REQUIREMENT |

|

Type of Material |

STAINLESS STEEL SOFT, DEEP DRAW, EXTRA DEEP DRAW, QUARTER HARD, HALF HARD, FULL HARD. |

|

Form |

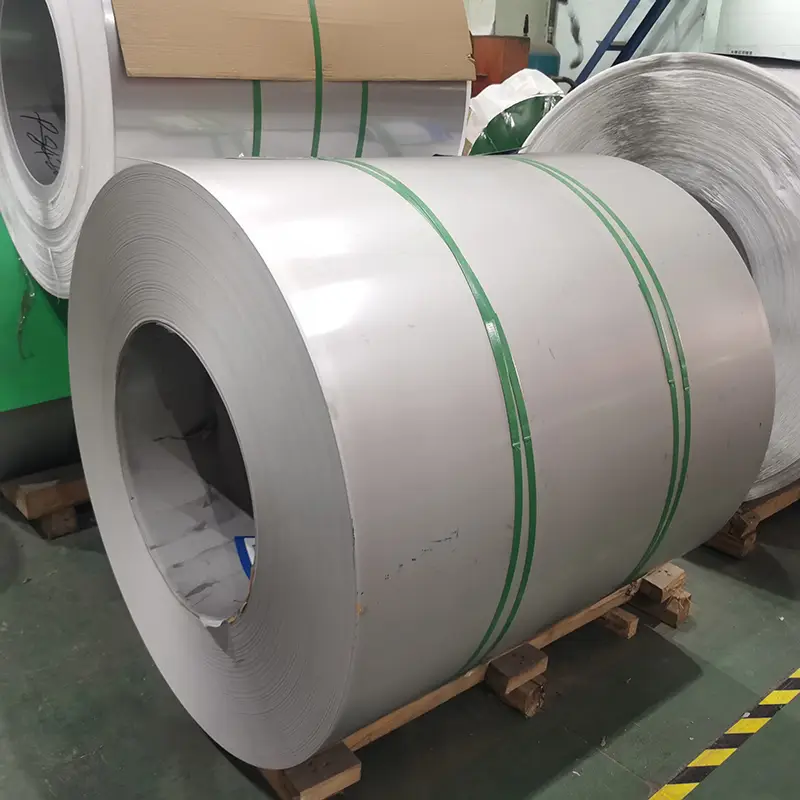

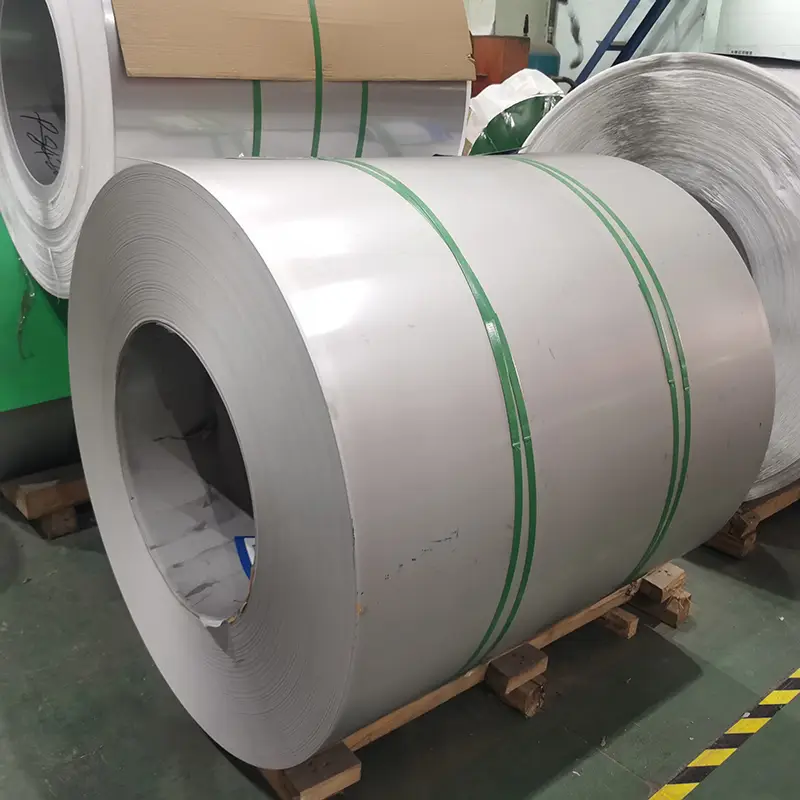

Coil / Strip |

|

Finish |

NO.1, 2B, 2D, 2H, 2R, No.4, HAIRLINE, SCOTCH BRITE, SATIN FINISH, NO.8, BA. |

Equivalent Material

|

Grade |

UNS |

AISI |

BS |

DIN |

EN |

JIS |

GB |

|

SS 410 |

S41000 |

410 |

410S21 |

1.4006 |

X12Cr13 |

SUS410 |

1Cr13 |

|

SS 410S |

S41008 |

410S |

|

1.4000 |

|

|

00Cr12 |

Chemical Composition

|

Grade |

Cr |

Mn |

Si |

Ni |

C |

P |

S |

Fe |

|

SS 410 |

11.50 – 13.50 |

≤1.50 |

≤1.00 |

≤ 0.75 |

0.08 – 0.15 |

0.04 |

0.02 |

Balance |

|

SS 410S |

11.50–13.50 |

1.00 max |

1.00 |

0.20-0.55 |

0.08 |

0.040 |

0.030 |

Balance |

Mechanical Properties

|

Grades |

Tensile Strength (Mpa) |

0.2% Offset Yield Strength (Mpa) |

Elongation, % in 2″ (51 mm) |

Hardening Response HRC |

|

SS 410 / 410S |

450– 510 |

205 – 290 |

20 – 34 |

38-45 |

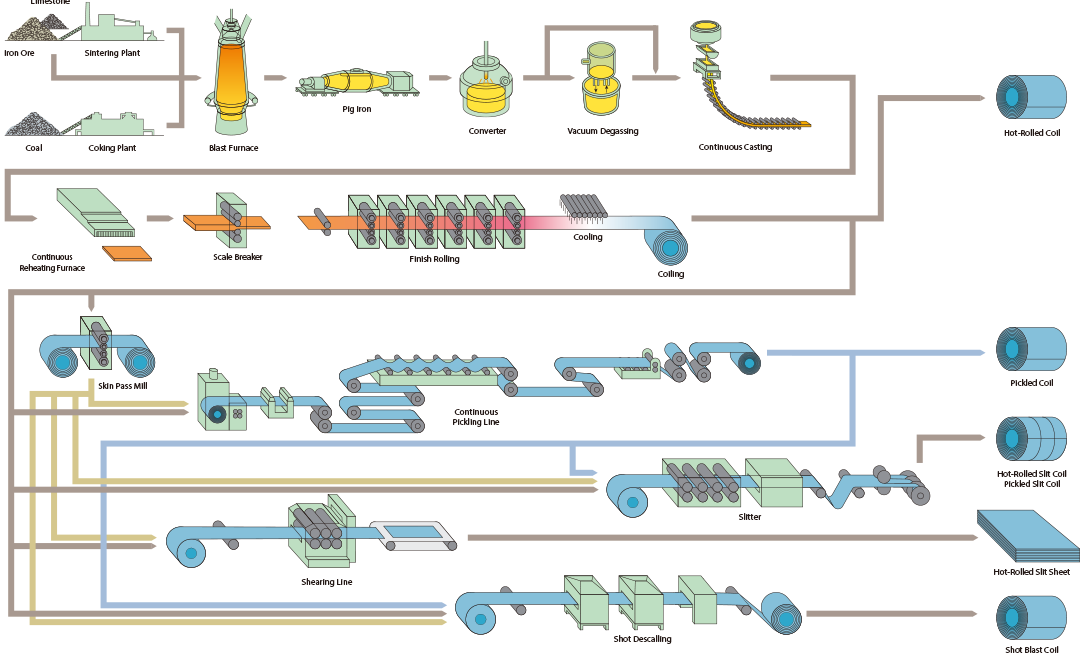

Hot-Rolled Steel Sheets and Coils

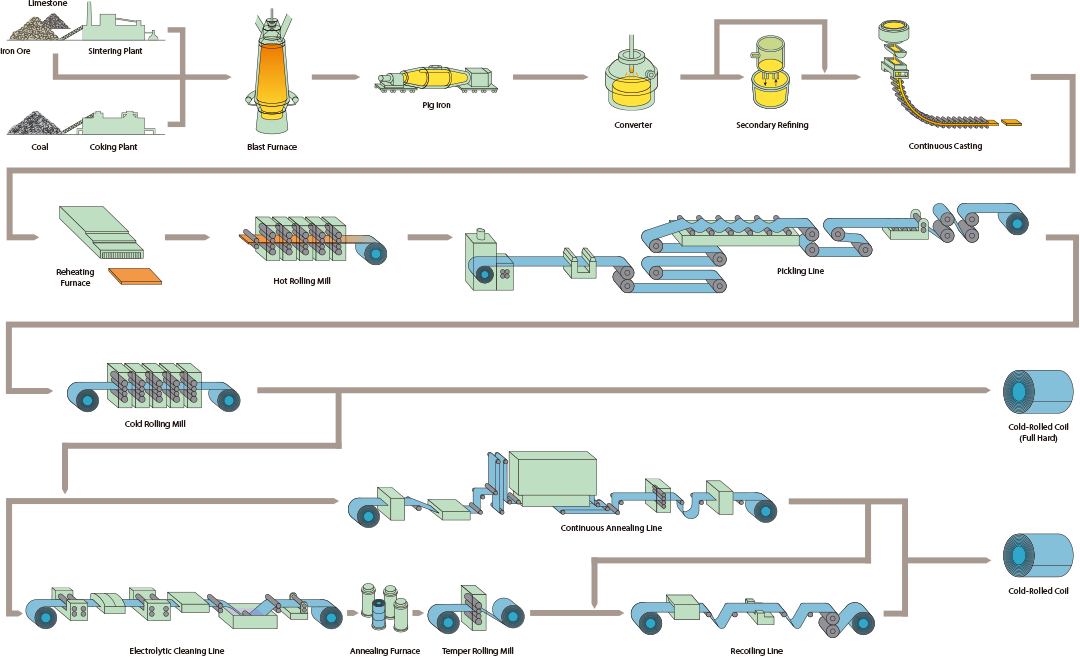

Cold-Rolled Steel Sheets and Coils