carbon steel plate,steel coil,stainless steel plate,china export service provider.

carbon steel plate,steel coil,stainless steel plate,china export service provider.

309, 309S and 309H stainless steel plate are chromium-nickel austenitic stainless steel grades that are commonly used in environments with elevated temperatures. Due to their high chromium and nickel content, these grades of stainless steel plate are highly corrosive resistant and have outstanding resistance to oxidation as well as excellent heat resistance. This type of stainless steel also provides excellent strength at room and elevated temperatures. The main difference between 309 and 309S stainless steel lies in the carbon content. 309S contains much less carbon which minimizes carbide precipitation and improves weldability. 309H differs from 309 plate in the amount of carbon as well. 309H contains more carbon than 309, this results in an enhanced creep resistance.

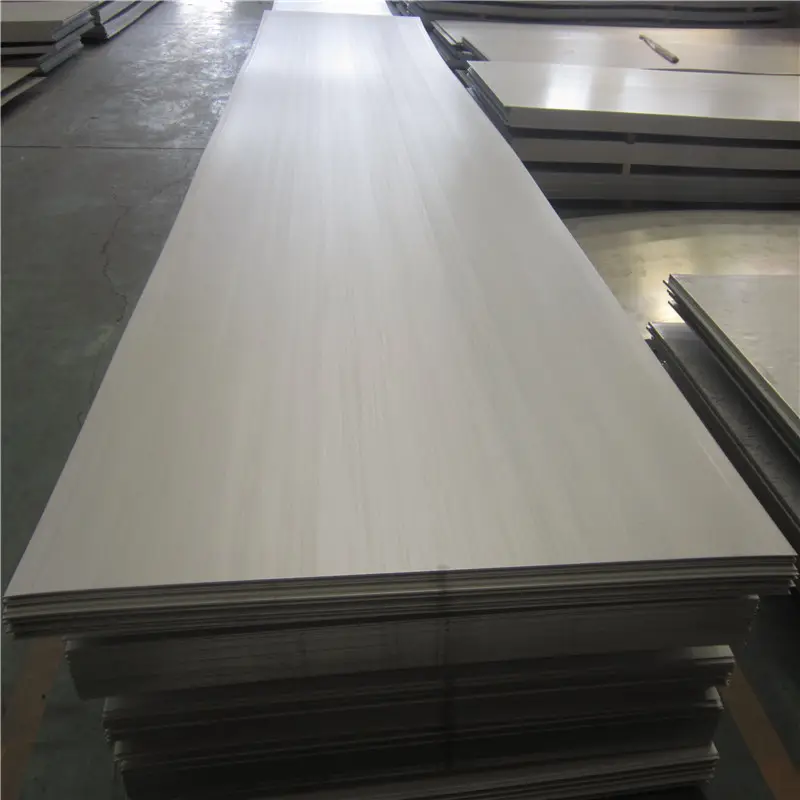

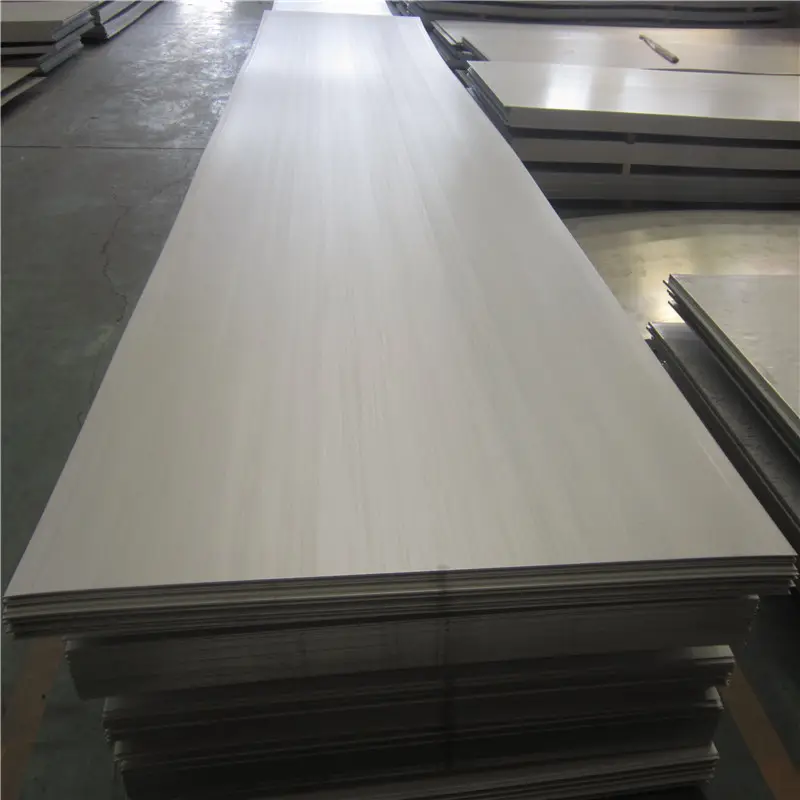

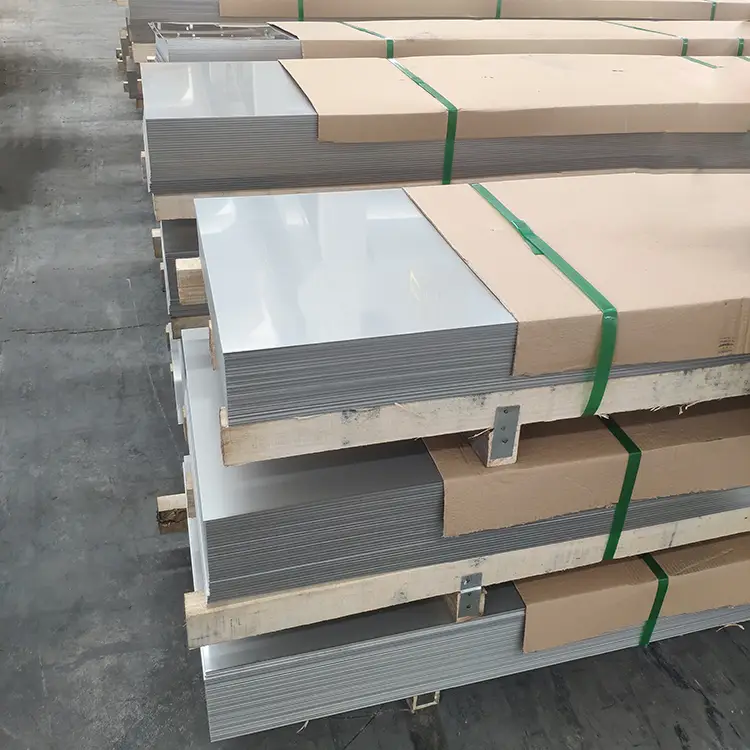

This plate is available in mill plate, and coil plate. It can be purchased in thicknesses ranging from 0.188” to 1.5”. It is available in coil plate lengths of 96 “, 120”, 144”, but custom lengths are also available per customer request. This type of stainless steel plate is available in plate in plate mill plate in a variety of mill sizes.

Alloy 309/309S (UNS S30900/S30908) austenitic stainless steel is typically used for elevated temperature applications. Its high chromium and nickel content provides comparable corrosion resistance, superior resistance to oxidation, and the retention of a larger fraction of room temperature strength than the common austenitic Alloy 304

Hot and Cold Working

Grade 309 tempered steel is hot worked at 1177°C (2150°F) trailed by warming at 982°C (1800°F). It tends to be at that point extinguished quickly. Post-work toughening should be possible to reestablish its erosion opposition property. Grade 309s tempered steel can be going, vexed, drawn, and stepped despite the fact that it has a high work solidifying rate. Strengthening is performed after the virus working so as to decrease inside pressure.

Annealing and Hardening

Stainless Steel 309S treated steel can be toughened at a temperature extending from 1038 to 1121°C (1900 to 2050°F) and afterwards extinguished with water. Grade 309 hardened steel doesn’t respond to warm treatment. Quality and hardness of this combination can be expanded by cool working.

|

Thick (mm) |

Width (mm) |

Length (mm) |

Surface Finish |

|

0.3 |

1219 , 1000 |

2438, 2000, other |

2B, BA, NO.4, NO.8, HL |

|

0.4 |

1219, 1000 |

2438, 2000, other |

2B, BA, NO.4, NO.8, HL |

|

0.5 |

1219, 1000 |

2438, 2000, other |

2B, BA, NO.4, NO.8, HL |

|

0.6 |

1219, 1000 |

2438, 2000, other |

2B, BA, NO.4, NO.8, HL |

|

0.7 |

1219, 1000 |

2438, 2000, other |

2B, BA, NO.4, NO.8, HL |

|

0.8 |

1219, 1000 |

2438, 2000, other |

2B, BA, NO.4, NO.8, HL |

|

0.9 |

1219, 1000 |

2438, 2000, other |

2B, BA, NO.4, NO.8, HL |

|

1.0 |

1219, 1000 |

2438, 2000, other |

2B, BA, NO.4, NO.8, HL |

|

1.2 |

1500, 1219, 1000 |

3000, 2438, 2000, other |

2B, BA, NO.4, NO.8, HL |

|

1.5 |

1500, 1219, 1000 |

3000, 2438, 2000, other |

2B, BA, NO.4, NO.8, HL |

|

2.0 |

1500, 1219, 1000 |

3000, 2438, 2000, other |

2B, BA, NO.4, NO.8, HL |

|

2.5 |

1500, 1219, 1000 |

3000, 2438, 2000, other |

2B, BA, NO.4, NO.8, HL |

|

3.0 |

1500, 1219, 1000 |

3000, 2438, 2000, other |

2B, BA, NO.4, NO.8, HL |

Tolerance Range

|

tolerance range of cold rolled stainless steel sheet/plate |

||||

|

Thickness |

Large Tolerance |

Normal Tolerance |

Small Tolerance |

No Tolerance |

|

0.4MM |

0.3-0.32 |

0.33-0.37 |

0.37-0.39 |

≥0.39 |

|

0.5MM |

0.4-0.42 |

0.43-0.47 |

0.47-0.49 |

≥0.49 |

|

0.6MM |

0.5-0.52 |

0.53-0.56 |

0.57-0.59 |

≥0.59 |

|

0.7MM |

0.6-0.62 |

0.63-0.67 |

0.67-0.69 |

≥0.69 |

|

0.8MM |

0.7-0.72 |

0.73-0.77 |

0.74-0.79 |

≥0.79 |

|

0.9MM |

0.8-0.82 |

0.83-0.87 |

0.87-0.89 |

≥0.89 |

|

1.0MM |

0.89-0.9 |

0.91-0.94 |

0.94-0.99 |

≥0.99 |

|

1.2MM |

1.02-1.08 |

1.09-1.15 |

1.16-1.18 |

≥1.18 |

|

1.5MM |

1.32-1.38 |

1.39-1.45 |

1.46-1.48 |

≥1.48 |

|

2.0MM |

1.72-1.79 |

1.8-1.86 |

1.87-1.9 |

≥1.9 |

|

2.5MM |

2.23-2.36 |

2.32-2.42 |

2.42-2.47 |

≥2.48 |

|

3.0MM |

2.7-2.77 |

2.78-2.85 |

2.85-2.9 |

≥2.9 |

|

tolerance range of hot rolled stainless steel sheet/plate |

||||

|

Thickness |

Large Tolerance |

Normal Tolerance |

Small Tolerance |

No Tolerance |

|

3.0MM |

2.6-2.75 |

2.75-2.85 |

2.86-2.9 |

≥2.9 |

|

4.0MM |

3.5-3.6 |

3.6-3.75 |

3.76-3.95 |

≥3.95 |

|

5.0MM |

4.5-4.6 |

4.6-4.75 |

4.75-4.95 |

≥4.95 |

|

6.0MM |

5.4-5.6 |

5.6-5.75 |

5.75-5.85 |

≥5.85 |

|

8.0MM |

7.3-7.5 |

7.5-7.65 |

7.65-7.85 |

≥7.85 |

|

10.0MM |

9.2-9.3 |

9.3-9.6 |

9.6-9.85 |

≥9.85 |

|

12.0MM |

11.1-11.2 |

11.2-11.6 |

11.6-11.85 |

≥11.85 |

|

14.0MM |

13.1-13.2 |

13.2-13.6 |

13.6-13.85 |

≥13.85 |

|

309 |

309S |

309H |

|

UNS S30900 |

UNS S30908 |

UNS S30909 |

|

ASTM A240 |

ASTM A240 |

ASTM A240 |

|

ASTM A480 |

ASTM A480 |

ASTM A480 |

|

ASME SA240 |

ASME SA240 |

ASME SA240 |

|

AMS 5523 |

AMS 5523 |

AMS 5523 |

Typical Creep Properties

|

Temperature |

Creep Strain (MPa) |

Creep Rapture (MPa) |

|||||

|

°C |

°F |

1000 H |

10000 H |

100000 H |

1000 H |

10000 H |

100000 H |

|

600 |

1112 |

120 |

80 |

40 |

190 |

120 |

65 |

|

700 |

1292 |

50 |

25 |

20 |

75 |

36 |

16 |

|

800 |

1472 |

20 |

10 |

8 |

35 |

18 |

7.5 |

|

900 |

1652 |

8 |

4 |

3 |

15 |

8.5 |

3 |

|

1000 |

1832 |

4 |

2.5 |

1.5 |

8 |

4 |

1.5 |

|

Element |

309 |

309S |

309H |

|

Chromium |

22.0 min.-24.0 max. |

22.0 min.-24.0 max. |

22.0 min.-24.0 max. |

|

Nickel |

12.0 min.-15.0 max. |

12.0 min.-15.0 max. |

12.0 min.-15.0 max. |

|

Carbon |

0.20 |

0.08 |

0.04 min.-0.10 max. |

|

Manganese |

2.00 |

2.00 |

2.00 |

|

Phosphorus |

0.045 |

0.045 |

0.045 |

|

Sulfer |

0.030 |

0.030 |

0.030 |

|

Silicon |

0.75 |

0.75 |

0.75 |

|

Iron |

Balance |

Balance |

Balance |

Mechanical Properties

Typical Values at 68°F (20°C)

|

Yield Strength |

Ultimate Tensile |

Elongation |

Hardness |

||

|

psi (min.) |

(MPa) |

psi (min.) |

(MPa) |

% (min.) |

(max.) |

|

45,000 |

310 |

85,000 |

586 |

50 |

202 (HBN) |

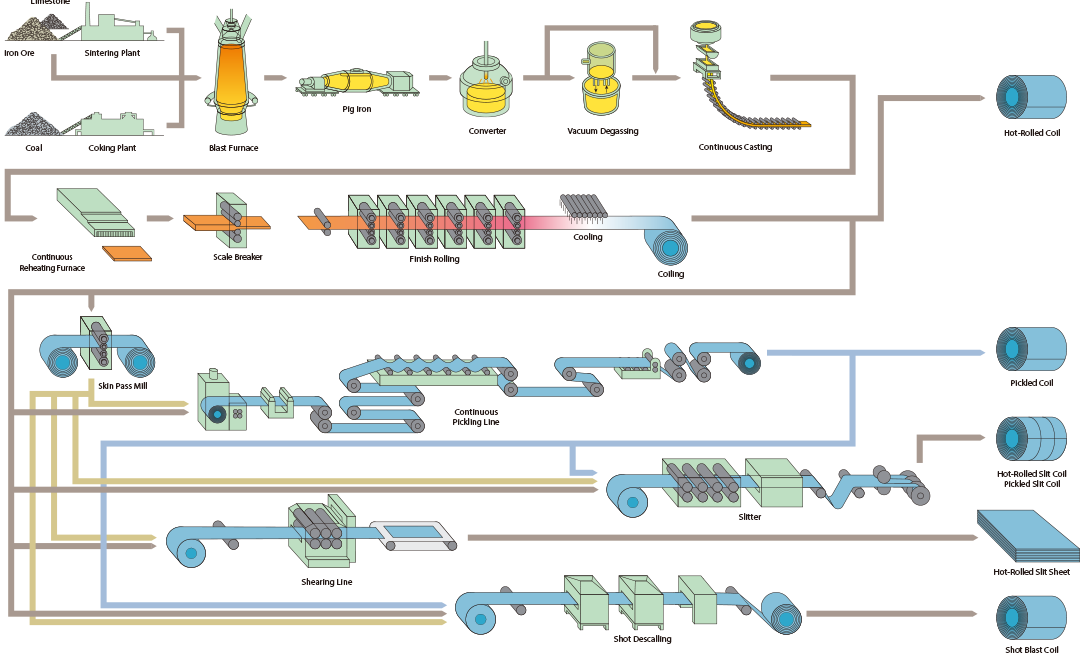

Hot-Rolled Steel Sheets and Coils

Cold-Rolled Steel Sheets and Coils