carbon steel plate,steel coil,stainless steel plate,china export service provider.

carbon steel plate,steel coil,stainless steel plate,china export service provider.

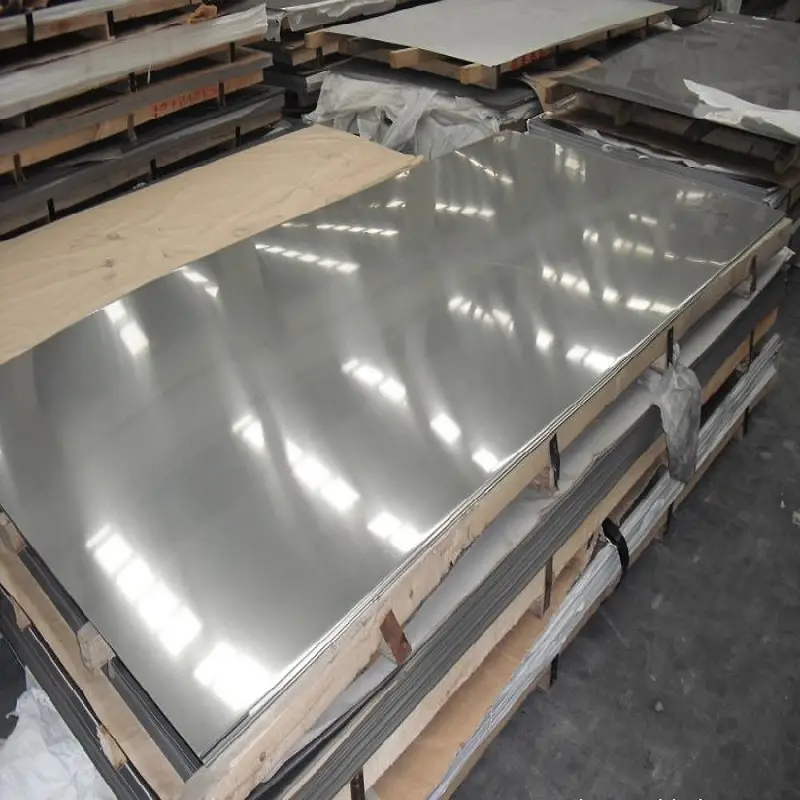

316 is molybdenum-bearing austenitic stainless steel, which increase general corrosion resistance, improves resistance to pitting from chloride ion solutions, and provides increased strength at elevated temperatures. The higher nickel and molybdenum content in this grade allows it to demonstrate better overall corrosion resistant properties than 304, especially with regard to pitting and crevice corrosion in chloride environments.

In addition, Alloy 316/ 316L provides excellent elevated temperature tensile, creep and stress-rupture strengths, as well as outstanding formability and weldability. 316L is the lower carbon version of 316 and is immune from sensitization; therefore, it is very frequently used in heavy gauge welded components.

Hot Forming

Working temperatures of 1700 – 2200°F (927 – 1204°C) are recommended for most hot working processes. For maximum corrosion resistance, the material should be annealed at 1900°F (1038°C) minimum and water quenched or rapidly cooled by other means after hot working.

Cold Forming

The alloy is quite ductile and forms easily. Cold working operations will increase the strength and hardness of the alloy and might leave it slightly magnetic.

Machining

Alloy 316/316L is subject to work hardening during deformation and is subject to chip breaking. The best machining results are achieved with slower speeds, heavier feeds, excellent lubrication, sharp tooling and powerful rigid equipment.

|

Operation |

Tool |

Lubrication |

CONDITIONS |

|||||

|

|

|

|

Depth-mm |

Depth-in |

Feed-mm/t |

Feed-in/t |

Speed-m/min |

Speed-ft/min |

|

Turning |

High Speed Steel |

Cutting Oil |

6 |

.23 |

0.5 |

.019 |

11-16 |

36.1-52.5 |

|

Turning |

High Speed Steel |

Cutting Oil |

3 |

.11 |

0.4 |

.016 |

18-23 |

59.1-75.5 |

|

Turning |

High Speed Steel |

Cutting Oil |

1 |

.04 |

0.2 |

.008 |

25-30 |

82-98.4 |

|

Turning |

Carbide |

Dry or Cutting Oil |

6 |

.23 |

0.5 |

.019 |

70-80 |

229.7-262.5 |

|

Turning |

Carbide |

Dry or Cutting Oil |

3 |

.11 |

0.4 |

.016 |

85-95 |

278.9-312.7 |

|

Turning |

Carbide |

Dry or Cutting Oil |

1 |

.04 |

0.2 |

.008 |

100-110 |

328.1-360.9 |

|

|

|

|

Depth of cut-mm |

Depth of cut-in |

Feed-mm/t |

Feed-in/t |

Speed-m/min |

Speed-ft/min |

|

Cutting |

High Speed Steel |

Cutting Oil |

1.5 |

.06 |

0.03-0.05 |

.0012-.0020 |

16-21 |

52.5-68.9 |

|

Cutting |

High Speed Steel |

Cutting Oil |

3 |

.11 |

0.04-0.06 |

.0016-.0024 |

17-22 |

55.8-72.2 |

|

Cutting |

High Speed Steel |

Cutting Oil |

6 |

.23 |

0.05-0.07 |

.0020-.0027 |

18-23 |

59-75.45 |

|

|

|

|

Drill ø mm |

Drill ø in |

Feed-mm/t |

Feed-in/t |

Speed-m/min |

Speed-ft/min |

|

Drilling |

High Speed Steel |

Cutting Oil |

1.5 |

.06 |

0.02-0.03 |

.0008-.0012 |

10-14 |

32.8-45.9 |

|

Drilling |

High Speed Steel |

Cutting Oil |

3 |

.11 |

0.05-0.06 |

.0020-.0024 |

12-16 |

39.3-52.5 |

|

Drilling |

High Speed Steel |

Cutting Oil |

6 |

.23 |

0.08-0.09 |

.0031-.0035 |

12-16 |

39.3-52.5 |

|

Drilling |

High Speed Steel |

Cutting Oil |

12 |

.48 |

0.09-0.10 |

.0035-.0039 |

12-16 |

39.3-52.5 |

|

|

|

|

|

|

Feed-mm/t |

Feed-in/t |

Speed-m/min |

Speed-ft/min |

|

Milling Profiling |

High Speed Steel |

Cutting Oil |

|

|

0.05-0.10 |

.002-.004 |

10-20 |

32.8-65.6 |

Alloy 316/316L can be readily welded by most standard processes. A post

weld heat treatment is not necessary.

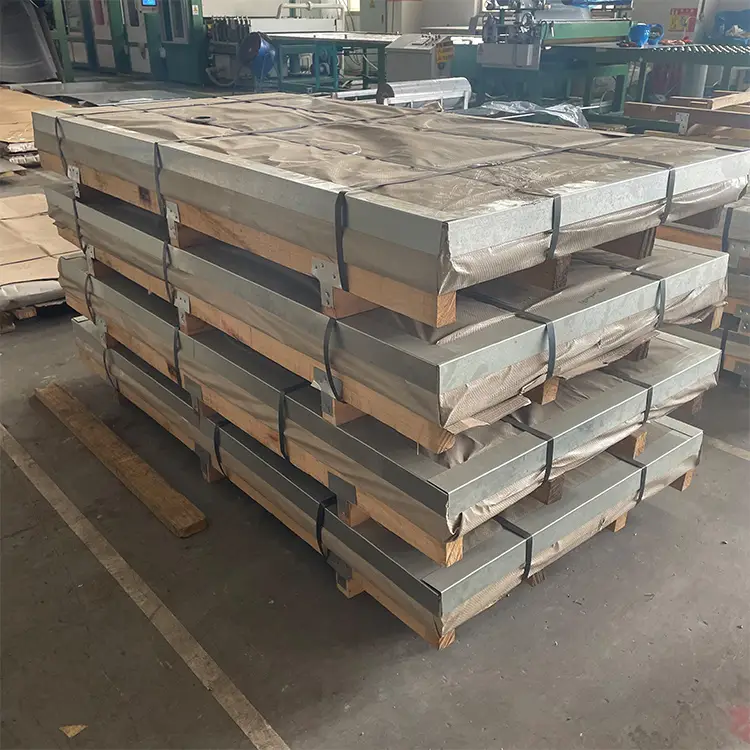

Available size

|

Thickness |

Width |

Length |

Surface Finish |

|

15-85 mm |

914, 1219, 1524 mm |

3048, 6069 mm |

Black |

|

3-8 mm |

20-1524 mm |

Container Loading: |

No.1 |

|

8 up - 60 mm |

30-1524 mm |

Max. 6096 mm |

No.1 |

Dimension and shape tolerance

|

Thickness |

Tolerance |

|

8.0 mm < T ≦ 10.0 mm |

±0.32 mm |

|

10.0 mm < T ≦ 25.0 mm |

±0.34 mm |

|

25.0 mm < T ≦ 85.0 mm |

±0.40 mm |

Stainless Steel Standards of 316/316L steel

|

Steel Standards of 316/316L |

|

|

316 |

316L |

|

ASTM A240 |

ASTM A240 |

|

ASTM A666 |

ASTM A666 |

|

ASME SA240 |

ASME SA240 |

|

AMS 5524 |

AMS 5507 |

Chemical Composition (%) of 316 Stainless Steel Plate

|

Element |

316 |

316L |

|

Chromium |

16.0 min.-18.0 max. |

16.0 min.-18.0 max. |

|

Nickel |

10.0 min.-14.0 max. |

10.0 min.-14.0 max. |

|

Molybdenum |

2.00 min.-3.00 max. |

2.00 min.-3.00 max. |

|

Carbon |

0.08 |

0.030 |

|

Manganese |

2.00 |

2.00 |

|

Phosphorus |

0.045 |

0.045 |

|

Sulfer |

0.03 |

0.03 |

|

Silicon |

0.75 |

0.75 |

|

Nitrogen |

0.1 |

0.1 |

|

Iron |

Balance |

Balance |

Mechanical Properties of 316 Stainless Steel Plate

|

0.2% Offset Yield Strength, ksi |

Ultimate Tensile Strength, ksi |

Elongation in 2 inches, % |

Hardness, Rockwell B |

|

25 min |

70 min |

40 min |

95 max |

Physical Properties of 316 Stainless Steel Plate

|

Density lb/inᶟ |

0.285 |

|

Density g/cmᶟ |

7.89 |

|

Melting Range |

2470-2555°F/1354 – 1402 °C |

|

Thermal Conductivity at 212°F (100°C) |

8.0 BTU/hr/ft²/ft/°F |

|

Thermal Conductivity at 212°F (100°C) |

10.8 W/m-°K |

|

Electrical Resistivity |

30.7 Microhm-in at 68°C |

|

Electrical Resistivity |

78 Microhm-cm at 20°C |

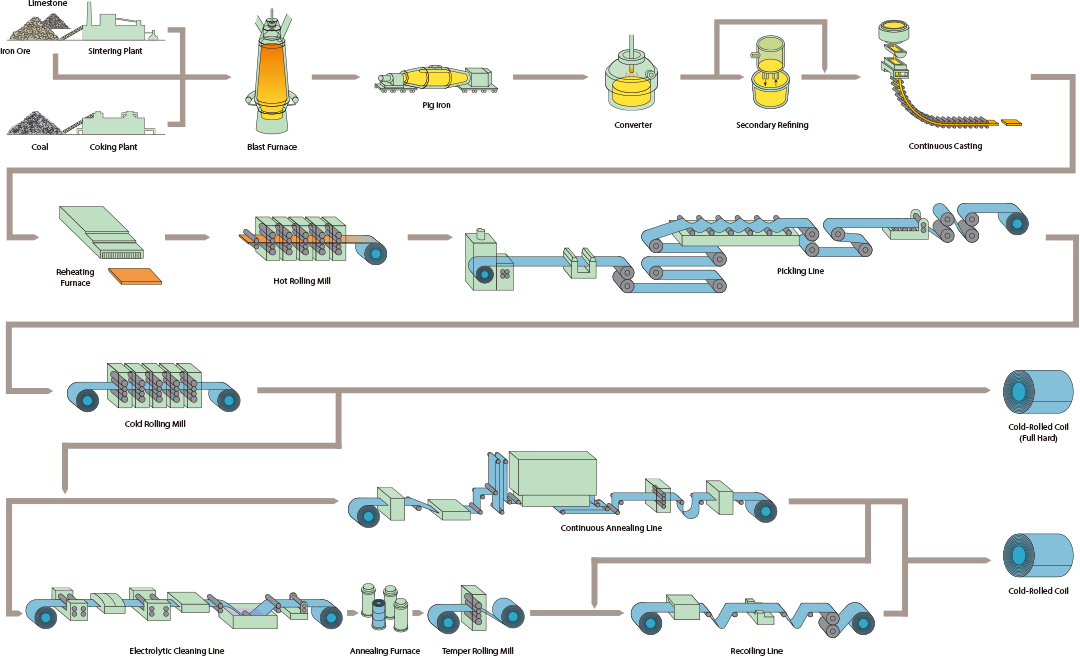

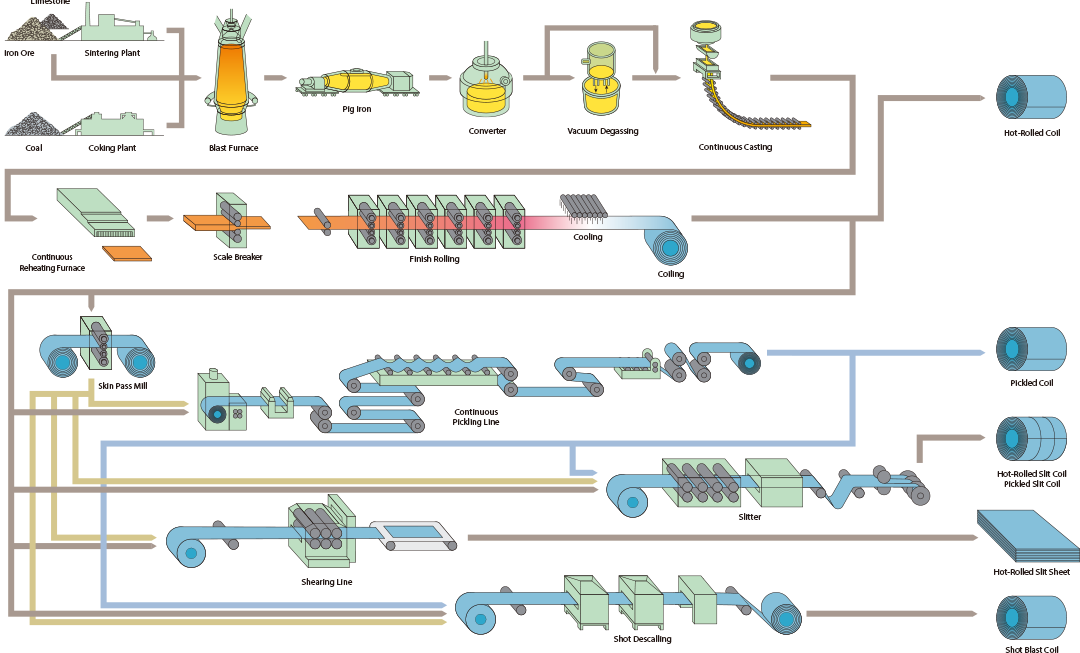

Hot-Rolled Steel Sheets and Coils

Cold-Rolled Steel Sheets and Coils