carbon steel plate,steel coil,stainless steel plate,china export service provider.

carbon steel plate,steel coil,stainless steel plate,china export service provider.

Alloy 321 (UNS S32100) is stabilized stainless steel plate which offers as its main advantage an excellent resistance to intergranular corrosion following exposure to temperatures in the chromium carbide precipitation range from 800 to 1500°F (427 to 816°C). Alloy 321 stainless steel plate is stabilized against chromium carbide formation by the addition of titanium

Alloy 321 stainless steel plate is also advantageous for high temperature service because of its good mechanical properties. Alloy 321 stainless steel plate offers higher creep and stress rupture properties than Alloy 304 and, particularly, Alloy 304L, which might also be considered for exposures where sensitization and intergranular corrosion are concerns.

General Properties

Alloy 321 (UNS S32100) is titanium stabilized austenitic stainless steel plate with good general corrosion resistance. It has excellent resistance to intergranular corrosion after exposure to temperatures in the chromium carbide precipitation range of 800 - 1500°F (427 - 816°C). The alloy resists oxidation to 1500°F (816°C) and has higher creep and stress rupture properties than alloys 304 and 304L. It also possesses good low temperature toughness.

Alloy 321H (UNS S 32109) stainless steel plate is the higher carbon (0.04 - 0.10) version of the alloy. It was developed for enhanced creep resistance and for higher strength at temperatures above 1000oF (537°C). In most instances, the carbon content of the plate enables dual certification.

Alloy 321 stainless steel plate cannot be hardened by heat treatment, only by cold working. It can be easily welded and processed by standard shop fabrication practices.

|

Specifications |

ASTM A240 TP 321 / ASME SA240 TP 321 / ASTM A240 TP 321H / ASME SA240 TP 321H |

|

Finish |

Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

|

Thickness |

4mm-100mm |

|

Length |

2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc |

|

Width |

1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc |

|

Hardness |

Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. |

|

Surface |

NO.1, NO.4, NO.8, 2B, 2D, BA, 8K, mirror, checkered, embossed, hair line, sand |

|

Form |

Perforated Sheet, Chequered Plate, Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

|

Value Added Service |

Polish, Rolling, Cutting, Bending, Forging, Cladding, Heat Treatment, Annealed, Pickling, Minor Fabrication Etc. |

|

|

Weight |

Est. Wt. per Plate |

|

7GA (.1874") |

|

|

|

48 x 96 |

7.871 |

251.9 |

|

48 x 120 |

7.871 |

314.8 |

|

48 x 144 |

7.871 |

377.8 |

|

10GA (.135”) |

|

|

|

36 x 120 |

5.670 |

170.1 |

|

48 x 96 |

5.670 |

181.4 |

|

48 x 120 |

5.670 |

226.8 |

|

60 x 120* |

5.670 |

283.5 |

|

60 x 144* |

5.670 |

340.2 |

|

72 x 120* |

5.670 |

340.2 |

|

11 GA (.120") |

|

|

|

36 x 96 |

5.040 |

121.0 |

|

36 x 120 |

5.040 |

151.2 |

|

36 x 144 |

5.040 |

181.4 |

|

48 x 96 |

5.040 |

161.3 |

|

48 x 120 |

5.040 |

304.6 |

|

48 x 144 |

5.040 |

241.9 |

|

60 x 120 |

5.040 |

252.0 |

|

60 x 144 |

5.040 |

302.4 |

|

72 x 120* |

5.040 |

302.4 |

|

72 x 144* |

5.040 |

362.9 |

|

12 Ga. (.105") |

|

|

|

36 x 96 |

4.410 |

105.8 |

|

36 x 120 |

4.410 |

132.3 |

|

36 x 144 |

4.410 |

158.8 |

|

42 x 120 |

4.410 |

154.4 |

|

48 x 96 |

4.410 |

141.1 |

|

48 x 120 |

4.410 |

176.4 |

|

48 x 144 |

4.410 |

211.7 |

|

60 x 96 |

4.410 |

176.4 |

|

60 x 120 |

4.410 |

220.5 |

|

60 x 144 |

4.410 |

264.6 |

|

72 x 120* |

4.410 |

264.6 |

|

72 x 144 |

4.410 |

317.5 |

|

13 Ga (.090") |

|

|

|

36 x 96 |

3.780 |

90.72 |

|

36 x 120 |

3.780 |

113.4 |

|

48 x 120 |

3.780 |

151.2 |

|

14 Ga. (.075") |

|

|

|

30 x 120 |

3.150 |

78.75 |

|

36 x 96 |

3.150 |

75.60 |

|

36 x 120 |

3.150 |

94.50 |

|

36 x 144 |

3.150 |

113.4 |

|

42 x 120 |

3.150 |

110.3 |

|

42 x 144 |

3.150 |

132.3 |

|

48 x 96 |

3.150 |

100.8 |

|

48 x 120 |

3.150 |

126.0 |

|

48 x 144 |

3.150 |

151.2 |

|

60 x 120 |

3.150 |

157.5 |

|

60 x 144 |

3.150 |

189.0 |

|

72 x 120 |

3.150 |

189.0 |

|

72 x 144 |

3.150 |

226.8 |

|

16 Ga. (.060") |

|

|

|

30 x 96 |

2.520 |

50.40 |

|

30 x 120 |

2.520 |

63.00 |

|

36 x 96 |

2.520 |

60.48 |

|

36 x 120 |

2.520 |

75.60 |

|

36 x 144 |

2.520 |

90.72 |

|

42 x 120 |

2.520 |

88.20 |

|

48 x 96 |

2.520 |

80.64 |

|

48 x 120 |

2.520 |

100.8 |

|

48 x 144 |

2.520 |

121.0 |

|

60 x 96 |

2.520 |

100.8 |

|

60 x 120 |

2.520 |

126.0 |

|

60 x 144 |

2.520 |

151.2 |

|

18 Ga. (.048") |

|

|

|

30 x 96 |

2.016 |

40.32 |

|

30 x 120 |

2.016 |

50.40 |

|

36 x 96 |

2.016 |

48.38 |

|

36 x 120 |

2.016 |

60.48 |

|

36 x 144 |

2.016 |

72.58 |

|

42 x 120 |

2.016 |

70.56 |

|

48 x 96 |

2.016 |

64.51 |

|

48 x 120 |

2.016 |

80.64 |

|

48 x 144 |

2.016 |

96.77 |

|

60 x 120 |

2.016 |

100.8 |

|

60 x 144 |

2.016 |

121.0 |

|

19 Ga. (.042") |

|

|

|

36 x 120 |

1.764 |

52.92 |

|

20 Ga. (.036") |

|

|

|

30 x 96 |

1.512 |

30.24 |

|

30 x 120 |

1.512 |

37.80 |

|

36 x 96 |

1.512 |

36.29 |

|

36 x 120 |

1.512 |

45.36 |

|

36 x 144 |

1.512 |

54.43 |

|

42 x 120 |

1.512 |

52.92 |

|

48 x 96 |

1.512 |

48.38 |

|

48 x 120 |

1.512 |

60.48 |

|

48 x 144 |

1.512 |

72.58 |

|

22 Ga. (.030") |

|

|

|

30 x 96 |

1.260 |

25.20 |

|

30 x 120 |

1.260 |

61.50 |

|

36 x 96 |

1.260 |

30.24 |

|

36 x 120 |

1.260 |

37.80 |

|

36 x 144 |

1.260 |

45.36 |

|

48 x 96 |

1.260 |

40.32 |

|

48 x 120 |

1.260 |

50.40 |

|

24 Ga. (.024") |

|

|

|

30 x 96 |

1.008 |

20.16 |

|

30 x 120 |

1.008 |

25.20 |

|

36 x 96 |

1.008 |

24.19 |

|

36 x 120 |

1.008 |

30.24 |

|

48 x 96 |

1.008 |

32.26 |

|

48 x 120 |

1.008 |

40.32 |

|

26 Ga. (.018") |

|

|

|

30 x 96 |

.7560 |

15.12 |

|

30 x 120 |

.7560 |

18.90 |

|

36 x 96 |

.7560 |

18.14 |

|

36 x 120 |

.7560 |

22.68 |

|

48 x 96 |

.7560 |

24.1 |

|

48 x 120 |

.7560 |

30.24 |

|

28 Ga. (.015") |

|

|

|

36 x 96 |

.630 |

15.12 |

|

36 x 120 |

.630 |

18.90 |

|

ASTM |

A 240 |

|

ASME |

SA 240 |

|

AMS |

5510 |

Chemical Composition

|

Grade |

|

C |

Mn |

Si |

P |

S |

Cr |

Ni |

N |

Other |

|

321 |

Min |

– |

2.00 |

0.75 |

0.045 |

0.03 |

17.00 |

9.00 |

0.10 |

T=5(C+N) |

|

Max |

0.08 |

– |

– |

– |

– |

19.00 |

12.00 |

– |

||

|

321H |

Min |

0.04 |

2.00 |

0.75 |

0.045 |

0.03 |

17.00 |

9.00 |

0.10 |

T=4(C+N) |

|

Max |

0.10 |

– |

– |

– |

– |

19.00 |

12.00 |

– |

Mechanical Properties

|

Grades |

Tensile Strength |

Yield Strength 0.2%Proof |

Elongation (% in 50mm) min |

Hardness |

|

|

Rockwell (HR B) |

Brinell |

||||

|

|

(MPa) min |

(MPa) mm |

|

(HR B) |

(HB) |

|

321 |

515 |

205 |

40 |

95 max |

217 max |

|

321H |

515 |

205 |

40 |

95 max |

217 max |

Grade Specification Comparisons :

|

Grade |

UNS No. |

Old British |

Euronorm |

Swedish SS |

Japanese JIS |

|

|

BS |

En |

No. Name |

||||

|

321 |

S32100 |

321S31 |

58E, 58C |

1.4541 X6CrNi18-10 |

2337 |

SUS 321 |

|

321H |

S32109 |

321S51 |

– |

1.4878 X10CrNi18-10 |

– |

SUS 321H |

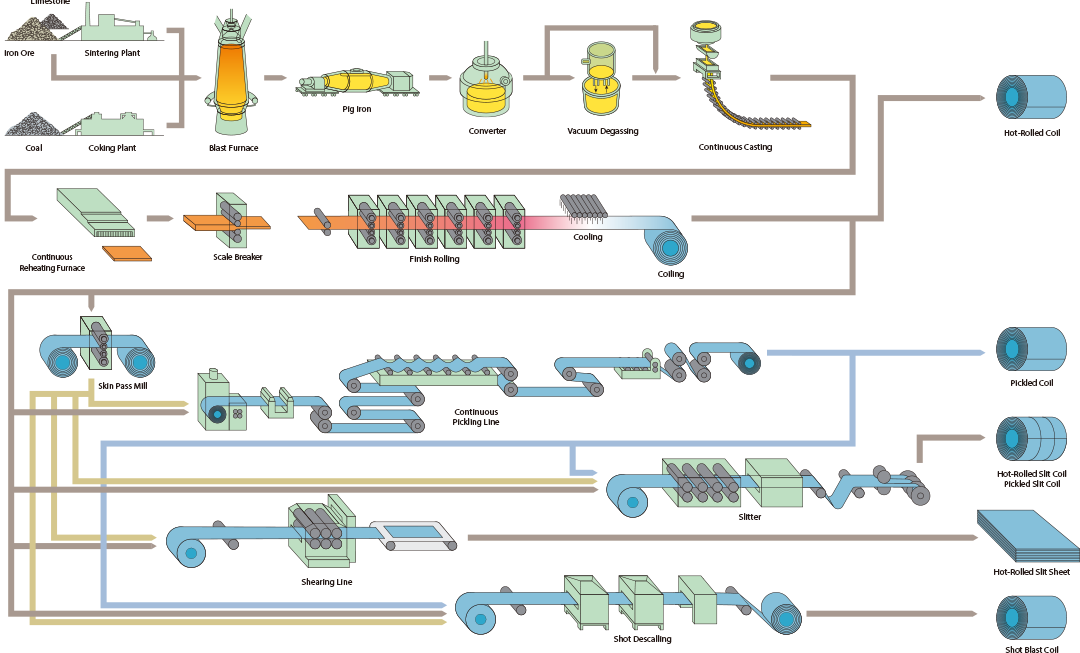

Hot-Rolled Steel Sheets and Coils

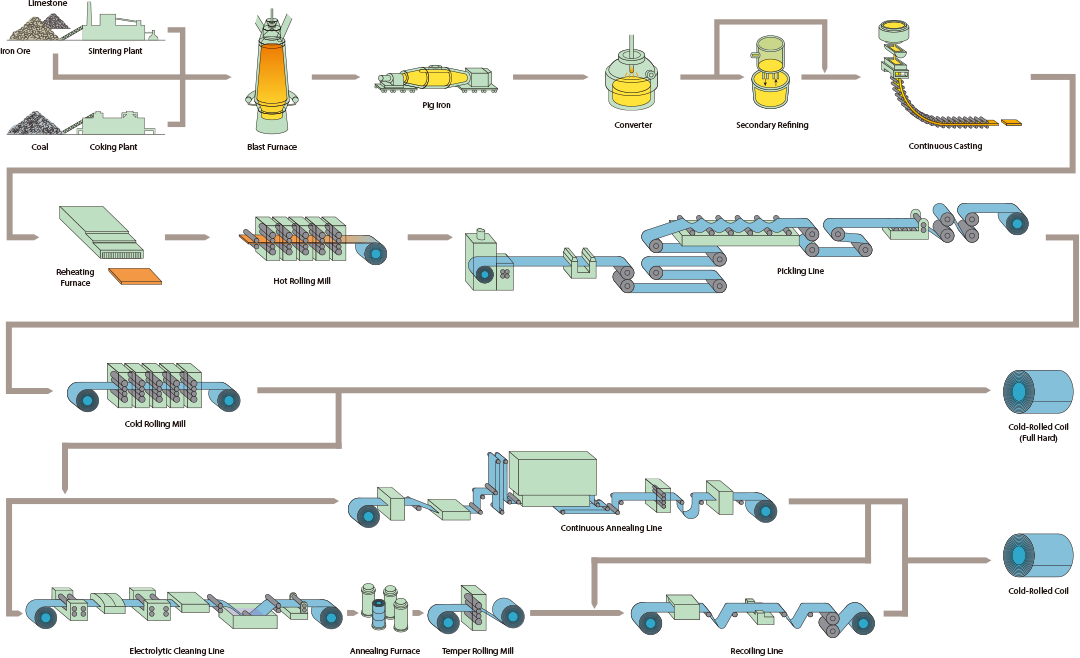

Cold-Rolled Steel Sheets and Coils