carbon steel plate,steel coil,stainless steel plate,china export service provider.

carbon steel plate,steel coil,stainless steel plate,china export service provider.

About Grade 310, 310S, 310H

Grade 310 (UNS S31000) and its various subgrades combine excellent high temperature

properties with good ductility and weldability.

Grade 310H (UNS S31009) has a carbon content restricted to exclude the lower end of the 310

range, so is the grade of choice for high temperature applications.

Grade 310S (UNS S31008) is used when the application environment involves moist corrodents in

a temperature range lower than that which is normally considered "high temperature" service. Thelower carbon content of 310S does reduce its high temperature strength compared to 310H.

Grade 310L is a series of proprietary grades, generally with a 0.03% maximum carbon and

sometimes used for very specific corrosive environments such as urea production.

Like other austenitic grades the 310 family have excellent toughness, even down to cryogenic

temperatures, although other grades are normally used in sub-zero environments.

|

Specifications |

ASTM A240 / ASME SA240 |

|

Thickness |

4mm-100mm |

|

Width |

1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc |

|

Length |

2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc |

|

Surface |

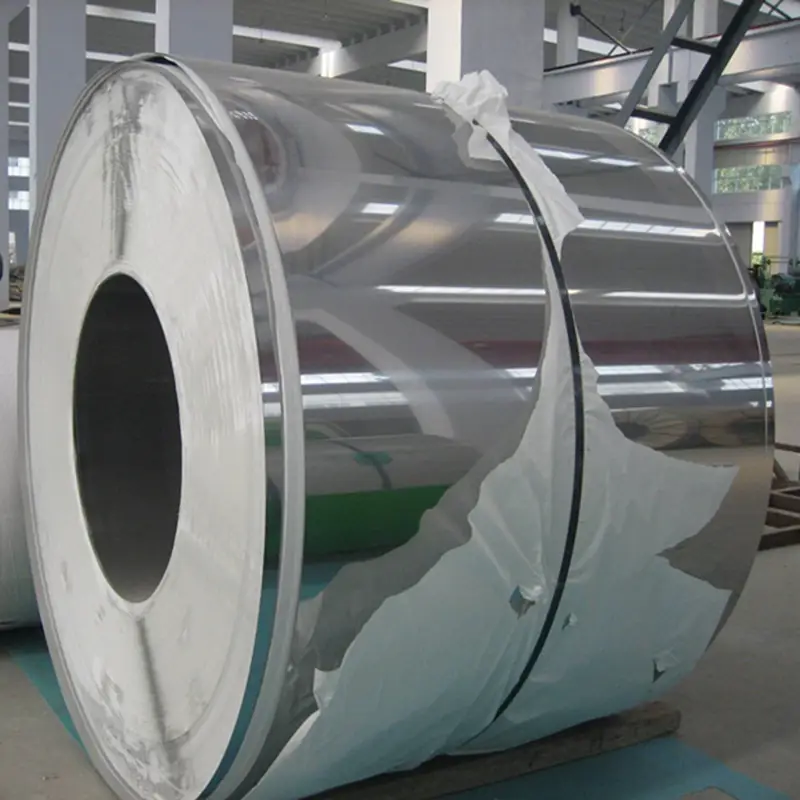

2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, checkered, embossed, hair line, sand |

|

Finish |

Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

|

Form |

Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc. |

|

Material |

Stainless Steel, Carbon Steel. Nickel Alloy, Hastelloy, Monel, Inconel, Titanium, Cupro, Alloy 20 |

|

310 |

310S |

310H |

|

UNS S31000 |

UNS S31008 |

UNS S31009 |

|

ASTM A240 |

ASTM A240 |

ASTM A240 |

|

ASTM A480 |

ASTM A480 |

ASTM A480 |

|

ASME SA240 |

ASME SA240 |

ASME SA240 |

|

AMS 5521 |

AMS 5521 |

AMS 5521 |

Chemical Analysis

|

Element |

310 |

310S |

310H |

|

Manganese |

2.00 |

2.00 |

2.00 |

|

Nickel |

19.0 min.-22.0 max. |

19.0 min.-22.0 max. |

19.0 min.-22.0 max. |

|

Phosphorus |

0.045 |

0.045 |

0.045 |

|

Carbon |

0.25 |

0.08 |

0.40 min. – 0.10 max. |

|

Chromium |

24.0 min.-26.0 max. |

24.0 min.-26.0 max. |

24.0 min.-26.0 max. |

|

Sulfur |

0.030 |

0.030 |

0.030 |

|

Iron |

Balance |

Balance |

Balance |

|

Silicon |

1.50 |

1.50 |

0.75 |

|

Phosphorus |

0.045 |

0.045 |

0.045 |

Weight % (all values are maximum unless a range is otherwise indicated)

EQUIVALENT GRADES

|

STANDARD |

WERKSTOFF NR. |

UNS |

JIS |

BS |

GOST |

AFNOR |

EN |

|

SS 310 |

1.4841 |

S31000 |

SUS 310 |

310S24 |

20Ch25N20S2 |

- |

X15CrNi25-20 |

|

SS 310S |

1.4845 |

S31008 |

SUS 310S |

310S16 |

20Ch23N18 |

- |

X8CrNi25-21 |

|

SS 310H |

- |

S31009 |

- |

- |

- |

- |

- |

MECHANICAL PROPERTIES

|

Density |

Melting Point |

Tensile Strength |

Yield Strength (0.2%Offset) |

Elongation |

|

8.0 g/cm3 |

1400 °C (2550 °F) |

Psi – 75000 , MPa – 515 |

Psi – 30000 , MPa – 205 |

35 % |

Possible Alternative Grades

|

Grade |

Why it might be chosen instead of 310, 310S, 310H |

|

3CR12 |

Heat resistance is needed, but only to about 600°C. |

|

304H H |

Heat resistance is needed, but only to about 800°C. |

|

321 |

Heat resistance is needed, but only to about 900°C. Subsequent aqueous corrosion resistance also required. |

|

253MA (UNS S30815) |

A slightly higher temperature resistance is needed than can be provided by 310. Better resistance to reducing sulphide atmosphere needed. Higher immunity from sigma phase embrittlement is required. |

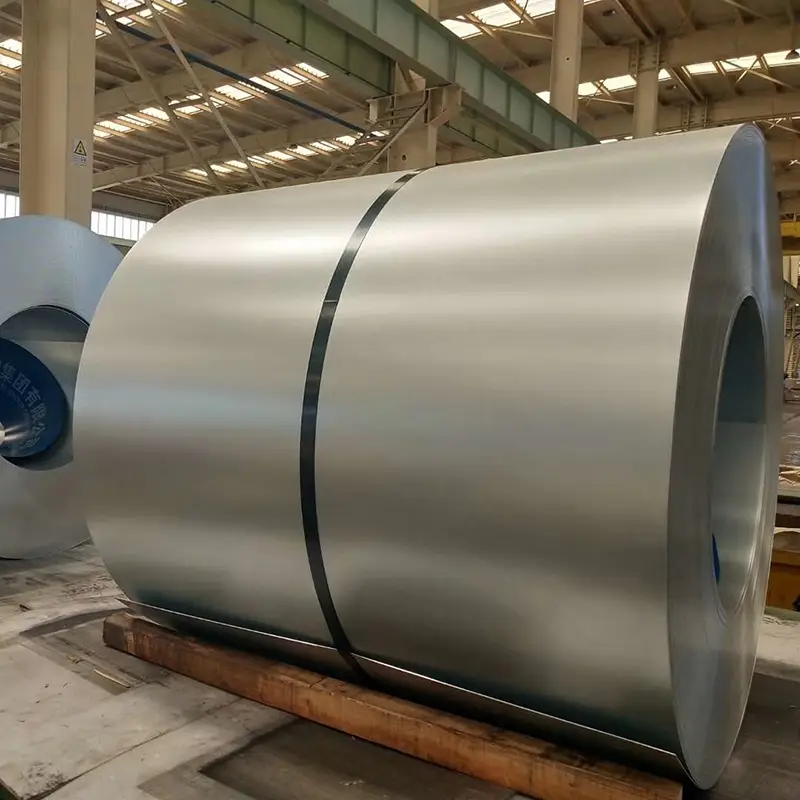

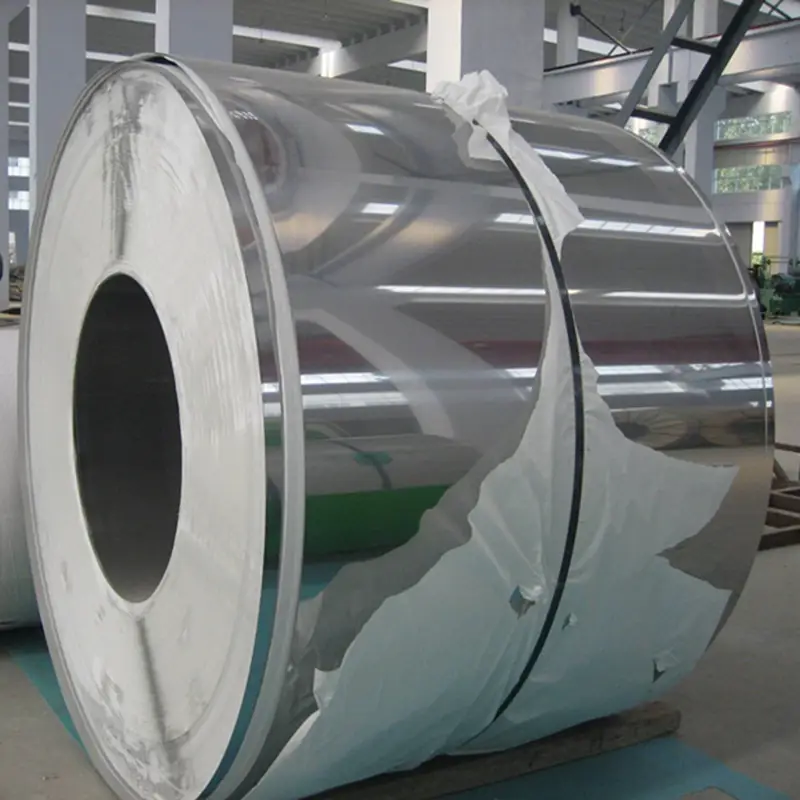

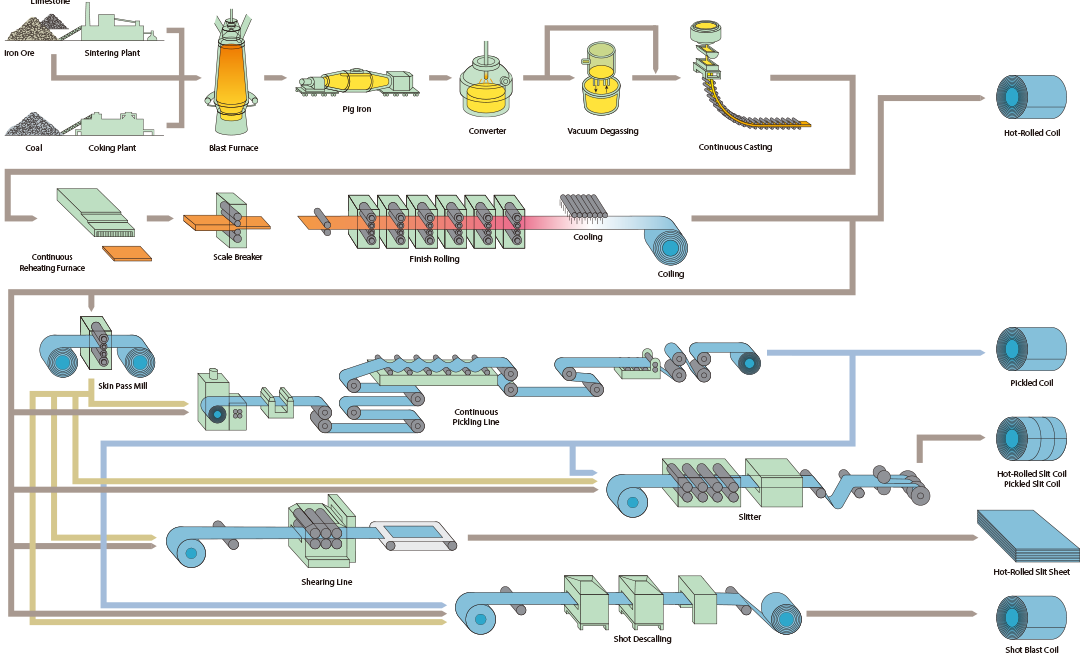

Hot-Rolled Steel Sheets and Coils

Cold-Rolled Steel Sheets and Coils