carbon steel plate,steel coil,stainless steel plate,china export service provider.

carbon steel plate,steel coil,stainless steel plate,china export service provider.

Alloys 309S is austenitic chromium-nickel stainless steel that is often used for higher temperature applications. Due to their high chromium and nickel content, Alloys 309S is highly corrosion resistant, has outstanding resistance to oxidation, and excellent heat resistance while providing good strength at room and elevated temperatures. The only significant difference between 309 and 309S is the carbon content. Alloy 309S has a much less carbon composition which minimizes carbide precipitation and improves weldability.

Alloy 309H Coils has some other features to offer such as precisely designed, rust proof, optimum finish, high strength, low maintenance, enhanced service life, and more.

Stainless Steel 309 Sheets, Plates & Coils Finishes

|

Surface Finish |

Definition |

Application |

|

2B |

Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. |

Medical equipment, Food industry, Construction material, Kitchen utensils. |

|

BA |

Those processed with bright heat treatment after cold rolling. |

Kitchen utensils, Electric equipment, Building construction. |

|

NO.3 |

Those finished by polishing with No.100 to No.120 abrasives specified in JIS R6001. |

Kitchen utensils, Building construction. |

|

NO.4 |

Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. |

Kitchen utensils, Building construction, Medical equipment. |

|

HL |

Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. |

Building Construction. |

|

NO.1 |

The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. |

Chemical tank, pipe |

|

Material |

17-4PH/17-7PH/2205/2507/S32760/F20/904/254SMO/XM-19/725LN/Inconel 600 625/ 800H/GH3030/Monel400/Nickel 200 201/Hastelloy C-276/317l/316Ti/309S/310s/347/ 321/316L/304L/431/F91 etc. |

|

Technical |

Cold rolled , hot rolled |

|

Width Range |

20mm-2000mm or customized |

|

cold rolled thickness |

0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.2 1.5 2.0 2.5 3.0 |

|

cold rolled width |

1000 1219 1500 1800 2000mm or as request |

|

Hot rolled thickness |

3.0 4.0 5.0 6.0 8.0 10.0 12 14 16 18 20 22 25 26-100mm |

|

Hot rolled width |

1250mm 1500mm, 1800 2000 |

|

One coil weight |

5-20 ton per coil, or divide to small coil according to customer's requirement |

|

309 |

309S |

309H |

|

UNS S30900 |

UNS S30908 |

UNS S30909 |

|

ASTM A240 |

ASTM A240 |

ASTM A240 |

|

ASTM A480 |

ASTM A480 |

ASTM A480 |

|

ASME SA240 |

ASME SA240 |

ASME SA240 |

|

AMS 5523 |

AMS 5523 |

AMS 5523 |

Typical Creep Properties

|

Temperature |

Creep Strain (MPa) |

Creep Rapture (MPa) |

|||||

|

°C |

°F |

1000 H |

10000 H |

100000 H |

1000 H |

10000 H |

100000 H |

|

600 |

1112 |

120 |

80 |

40 |

190 |

120 |

65 |

|

700 |

1292 |

50 |

25 |

20 |

75 |

36 |

16 |

|

800 |

1472 |

20 |

10 |

8 |

35 |

18 |

7.5 |

|

900 |

1652 |

8 |

4 |

3 |

15 |

8.5 |

3 |

|

1000 |

1832 |

4 |

2.5 |

1.5 |

8 |

4 |

1.5 |

Chemical Analysis

|

Element |

309 |

309S |

309H |

|

Chromium |

22.0 min.-24.0 max. |

22.0 min.-24.0 max. |

22.0 min.-24.0 max. |

|

Nickel |

12.0 min.-15.0 max. |

12.0 min.-15.0 max. |

12.0 min.-15.0 max. |

|

Carbon |

0.20 |

0.08 |

0.04 min.-0.10 max. |

|

Manganese |

2.00 |

2.00 |

2.00 |

|

Phosphorus |

0.045 |

0.045 |

0.045 |

|

Sulfer |

0.030 |

0.030 |

0.030 |

|

Silicon |

0.75 |

0.75 |

0.75 |

|

Iron |

Balance |

Balance |

Balance |

Mechanical Properties

Typical Values at 68°F (20°C)

|

Yield Strength |

Ultimate Tensile |

Elongation |

Hardness |

||

|

psi (min.) |

(MPa) |

psi (min.) |

(MPa) |

% (min.) |

(max.) |

|

45,000 |

310 |

85,000 |

586 |

50 |

202 (HBN) |

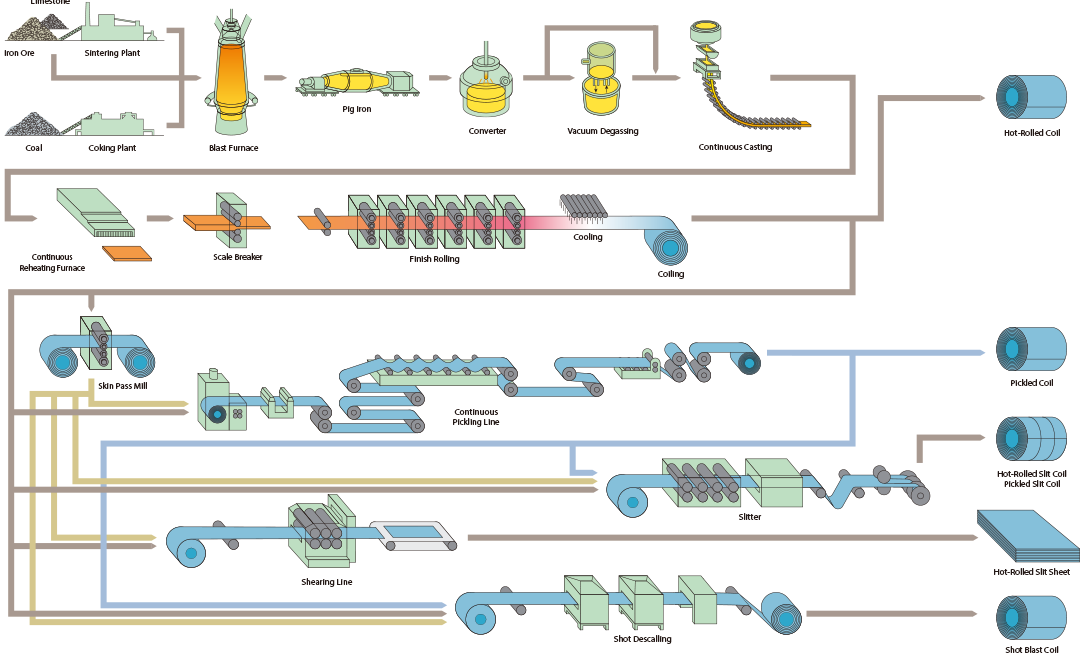

Hot-Rolled Steel Sheets and Coils

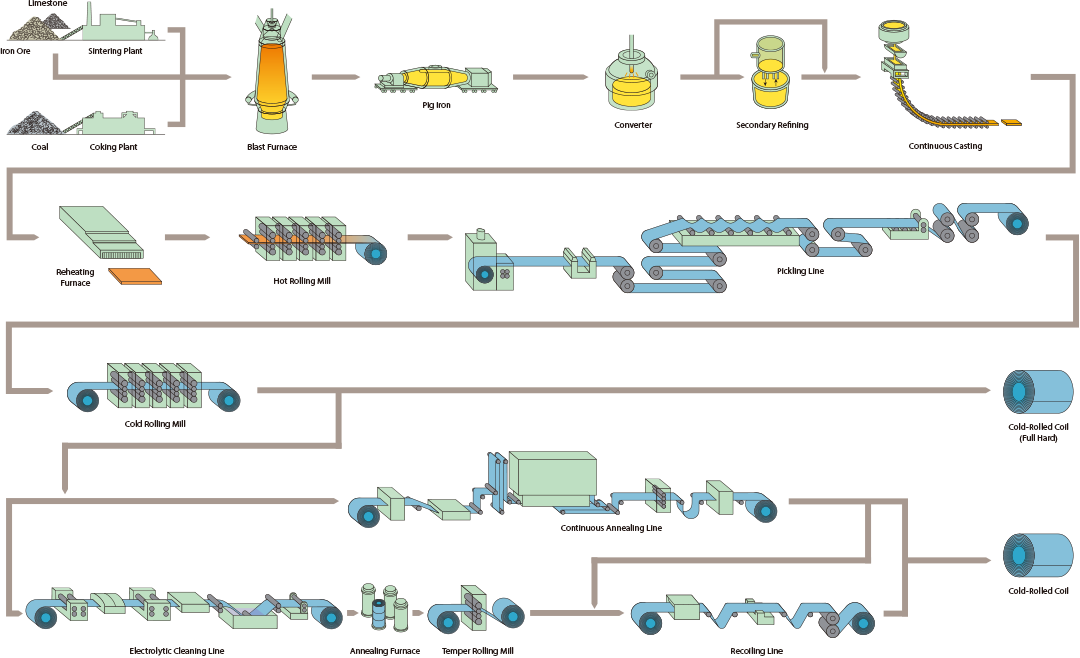

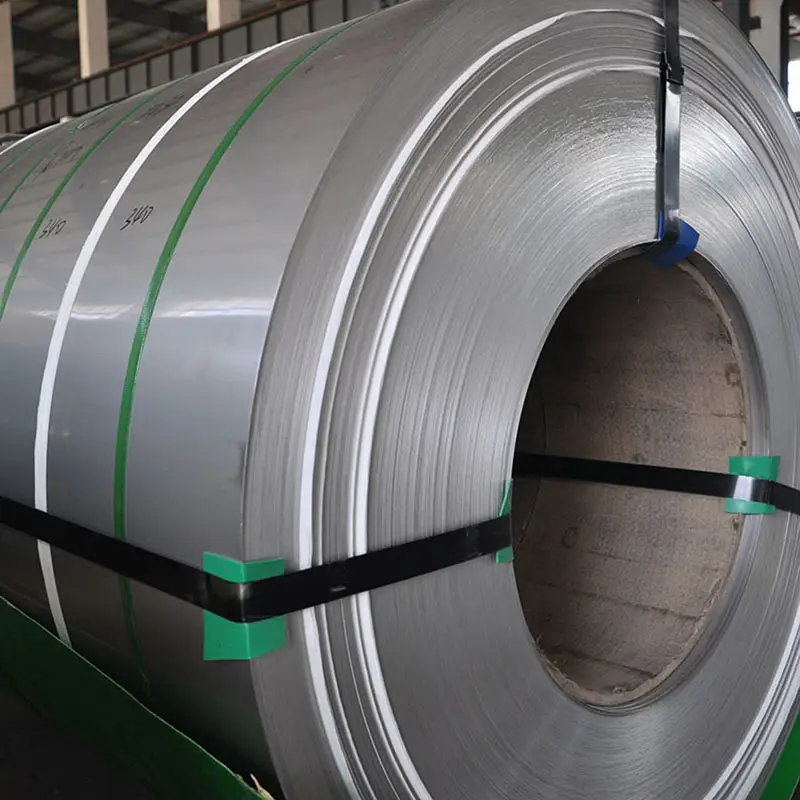

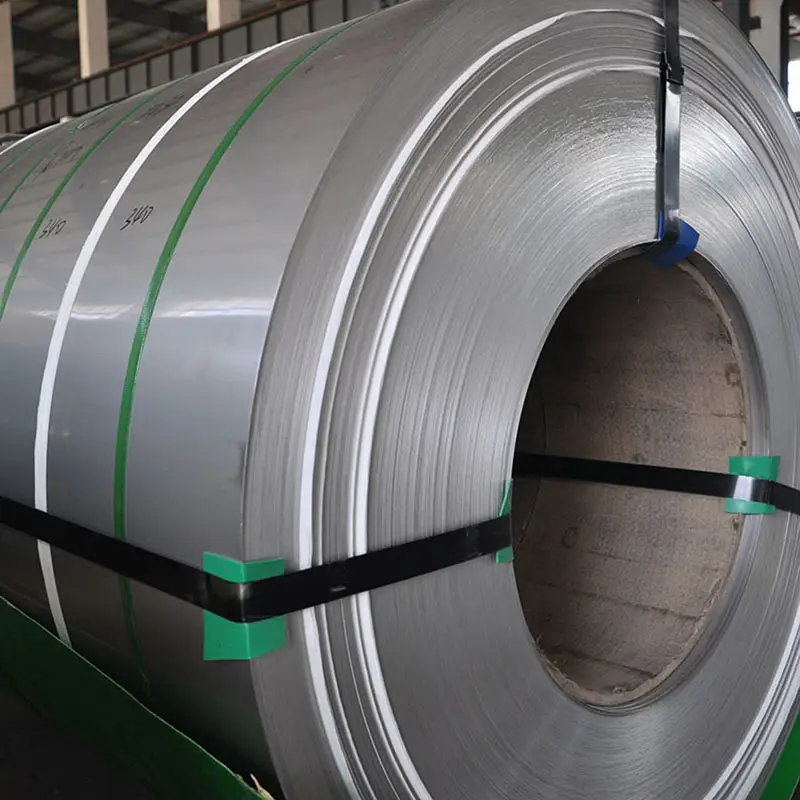

Cold-Rolled Steel Sheets and Coils