carbon steel plate,steel coil,stainless steel plate,china export service provider.

carbon steel plate,steel coil,stainless steel plate,china export service provider.

1.Air conditioning copper pipe can be roughly divided into ordinary air conditioning copper pipe and degreased air conditioning copper pipe:

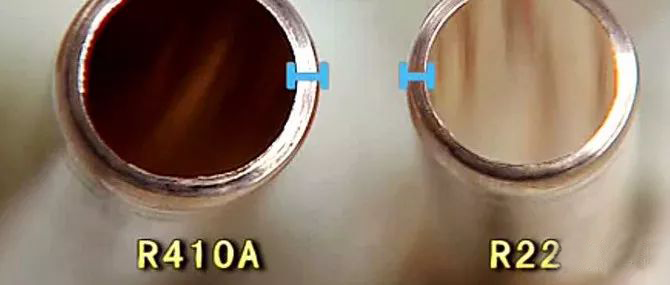

Ordinary air conditioning: the thickness is generally 2 points, 3 points 0.5mm thick, 4 points 0.6mm thick, 5 points and 6 points 0.7mm thick. Mainly used in R22.

Degreasing air conditioning copper pipe: also known as "degreasing air conditioning copper pipe", there are 2 points, 3 points is 0.8mm thick, 4 points, 5 points, 6 points is 1.0mm thick. Mainly used for R410 and other refrigerant.

2.The specific classification of air conditioning copper pipe materials:

Oxygen-free copper: including high purity oxygen-free copper (TU0, TU1, TU2) and phosphorus deoxidized copper (TUP, TP1, TP2, etc.), characterized by very little oxygen content, a small amount of deoxidizer remains in the deoxidized copper;

Aerobic copper: mainly ordinary pure copper (T1, T2, T3, etc.) and tough copper, characterized by high oxygen content;

Special copper: there are arsenic copper, silver copper, tellurium copper, etc., which are characterized by adding different trace alloying elements to achieve the purpose of improving the comprehensive performance of the material.

Now let's focus on copper and brass.

Copper pipe: The copper pipe used in our refrigeration industry is copper, with a copper content of more than 99.90%, which has the good characteristics of copper metal, a high-quality basic metal, widely used in various fields of industry and civil use, and plays an important role. There are three main categories: TP2, T2 and TU1.

TP2 is phosphorus deoxidized copper, containing 0.015-0.04% phosphorus, with good welding and cold bending properties, in the air conditioning refrigeration connection pipe, stove gas pipe connection pipe, electric heat pipe and other manufacturing fields are widely used.

T2 is pure copper, copper content is higher than 99.90%, when the user has high electrical conductivity requirements for the material, T2 copper pipe will be the first choice.

TU1 is oxygen-free copper, copper content ≥99.97%, oxygen and impurity content is very low, high purity, excellent electrical and thermal conductivity, good ductility, processing performance and welding, corrosion resistance, cold resistance are good. Due to the high requirements and high costs of its production, the price of its products is much higher than that of other categories of copper tubes.

Brass pipe: copper-zinc alloy pipe, the number after the letter H in the grade often represents the middle value of its copper content, and the zinc content is the rest. Different grades of brass pipes, with the increasing copper content, generally show better quality and extension performance. Mainly used as water pipe and wading connector.